In an era where precision and productivity drive competitiveness across sectors, selecting the right CNC milling machine can make all the difference. The GV2040 large worktable heavy-duty CNC milling machine, featuring a dual-column large travel design, stands out as a versatile solution widely deployed in automotive components, aerospace, mold making, engine manufacturing, and household appliance production. This article explores the GV2040’s distinct advantages within aerospace manufacturing, revealing how its stability and accuracy help overcome common cross-industry production challenges and efficiency bottlenecks.

Manufacturing today faces increasingly complex demands. Facilities that serve multiple industries often struggle with inconsistent equipment performance, limited work envelope, and prolonged setup times — all of which compromise throughput and quality. Aerospace manufacturing, with its stringent tolerances and large component sizes, requires machines capable of delivering consistent precision under heavy loads.

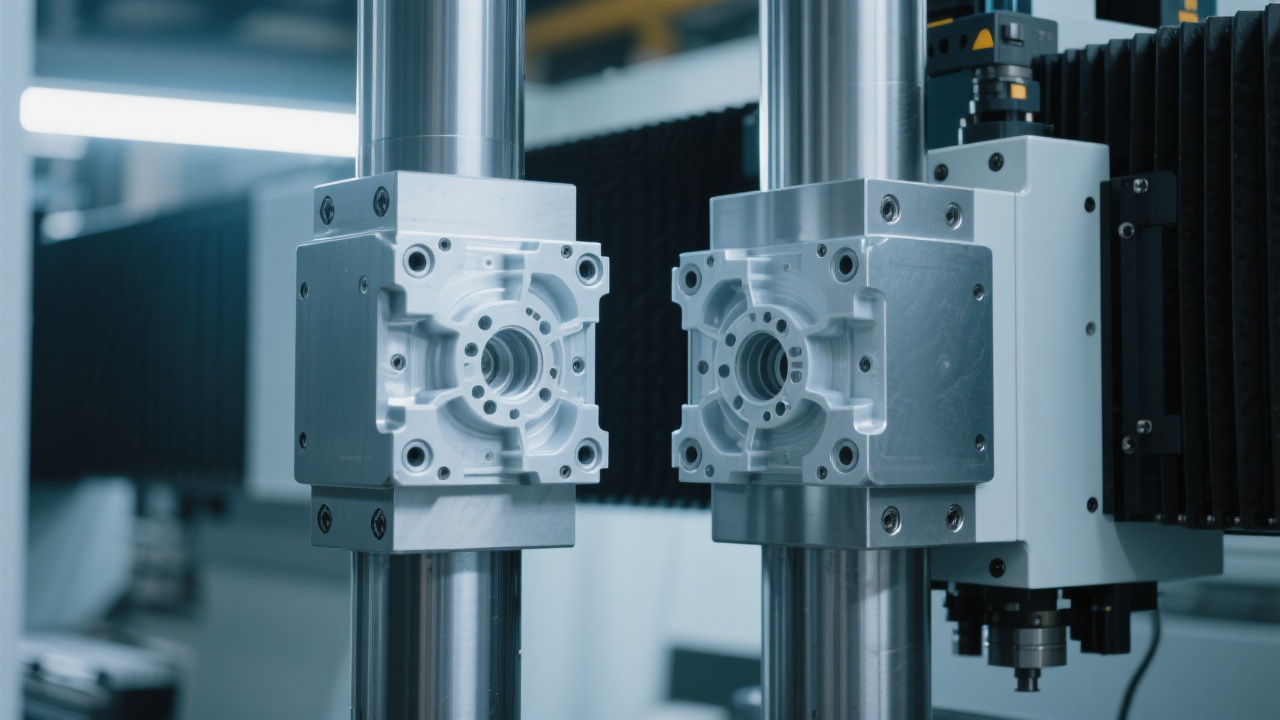

Engineered with a dual-column design, the GV2040 addresses these pain points by enhancing machine rigidity and expanding the working envelope to meet diverse profile and size requirements. This structural advantage enables stable cutting forces and precise movements, minimizing vibrations that can degrade part accuracy.

The GV2040 boasts several standout features critical to aerospace and multi-industry applications:

Collectively, these features enable aerospace manufacturers to reduce rework rates by up to 15% and increase throughput by approximately 20% compared to conventional milling centers.

The GV2040’s adaptability is exemplified across critical sectors:

| Industry | Application | Production Impact |

|---|---|---|

| Aerospace | Machining large titanium engine casings and structural airframes | 20% faster cycle times, ±0.008 mm precision, and 15% less rework |

| Automotive | High-volume production of drivetrain and chassis components | Improved throughput and decreased downtime due to rigid structure |

| Mold Making | Precision milling of injection molds with complex geometries | Enhanced surface finish and dimensional stability |

This cross-industry versatility enables manufacturers to optimize equipment investment by deploying one machine capable of handling diverse product lines without compromising quality.

A leading aerospace components manufacturer reported an increase in machining accuracy to ±0.0075 mm after integrating the GV2040 into their workflow, resulting in a 12% reduction in scrap and a solid improvement in part consistency. Similarly, an automotive supplier noted a 25% reduction in tool changeover time thanks to the GV2040’s stable platform and flexible fixturing.

These validated outcomes confirm the GV2040’s role as an enabler of manufacturing excellence and operational scalability.

Manufacturing sustainability and growth hinge on equipment that balances performance, versatility, and reliability. With ongoing R&D enhancements, the GV2040 aligns seamlessly with digitization trends, including IoT-ready controls and predictive maintenance compatibility, reducing unplanned downtime and operational costs.

Forward-thinking enterprises leveraging GV2040 position themselves to adapt nimbly across shifting industry demands — a competitive edge in today’s dynamic manufacturing landscape.

If your enterprise requires a milling machine that excels in aerospace manufacturing while boosting multi-industry adaptability and efficiency, the GV2040 presents a proven solution engineered to elevate your production capabilities and product quality.