In today's fiercely competitive manufacturing landscape, achieving both high precision and reliable stability across diverse industries is paramount. The GV2040 CNC milling machine stands out as a game-changer, particularly due to its innovative dual-column large travel configuration. This design elevates production capabilities in sectors such as automotive components, aerospace, mold making, engine manufacturing, and home appliances, by enabling seamless equipment integration and delivering exceptional machining performance.

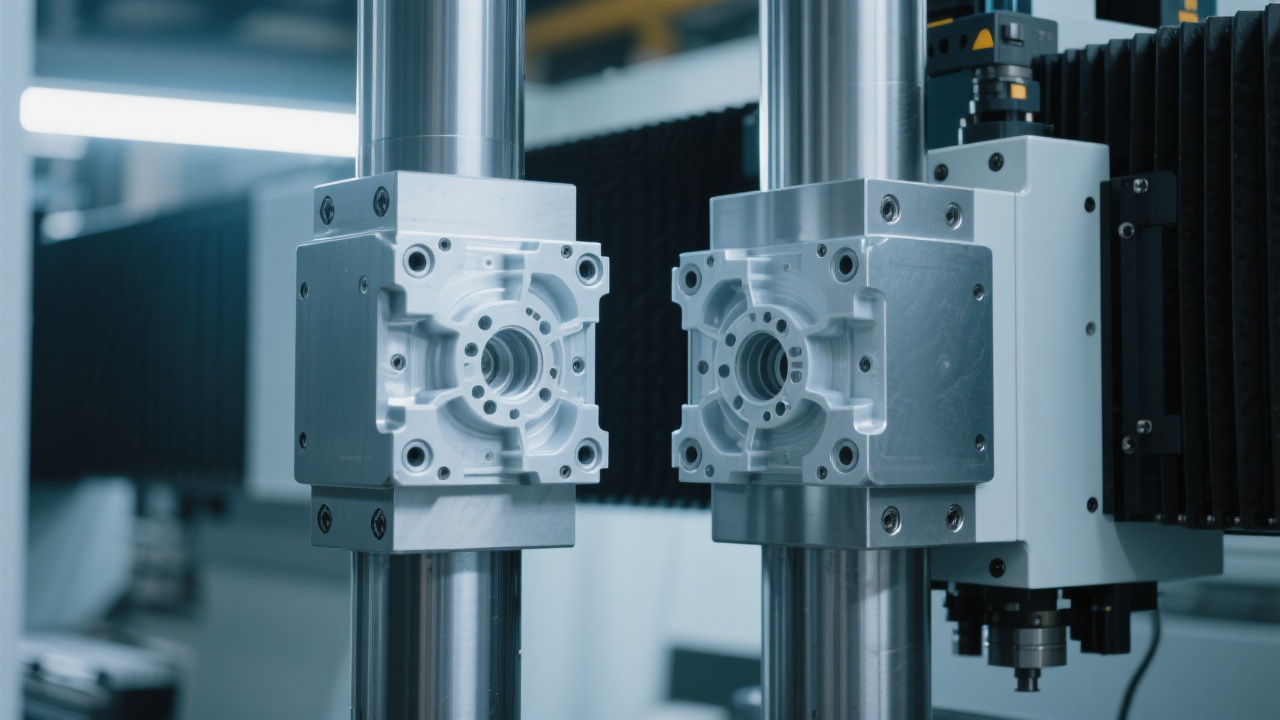

Manufacturers across key industries often grapple with production bottlenecks triggered by equipment limitations — notably instability, constrained working envelope, and imprecise operations that compromise output quality. The GV2040 solves these pain points by featuring a dual-column frame with an extended X-axis travel, allowing handling of large-sized workpieces without sacrificing rigidity.

Specifically, the GV2040 offers a worktable travel of 2000 mm (X), 1500 mm (Y), and 1200 mm (Z), accommodating complex and sizable parts common in heavy-duty mold and aerospace components. The robust dual-column structure minimizes deflection under heavy cutting loads, ensuring machining accuracy remains within ±0.01 mm guaranteed over continuous operations.

| Parameter | Specification |

|---|---|

| X-Axis Travel | 2000 mm |

| Y-Axis Travel | 1500 mm |

| Z-Axis Travel | 1200 mm |

| Positioning Accuracy | ±0.01 mm |

The GV2040 excels in integrating cutting-edge mechanical and control technologies:

The GV2040 has been successfully deployed by manufacturing leaders, contributing tangible improvements in output consistency and throughput:

In collaboration with a Tier 1 automotive supplier, the GV2040 enabled precision machining of complex engine blocks with up to 15% reduction in cycle time compared to legacy equipment, while maintaining strict surface finish requirements.

High-value aerospace parts requiring tight geometric tolerances benefited from GV2040’s stability, cutting rejection rates by 10% and enhancing compliance with NADCAP quality standards.

The increased travel and rigidity allowed mold manufacturers to machine larger dies with fewer setups, drastically decreasing downtime and increasing overall equipment effectiveness (OEE) by 12%.

One of the standout features of the GV2040 lies not just in its standalone capability but also in its ability to harmonize with other manufacturing equipment. Through standardized interface protocols and adaptable control software, it integrates effortlessly into automated production lines, enabling synchronized workflows. This coordination reduces manual interventions and eliminates bottlenecks, ultimately driving up throughput by an estimated 20%-25%.

With increasing demands for high-mix, low-volume production runs and growing automation levels, machines like GV2040 are strategic assets for manufacturers aiming to stay competitive. Its scalability, upgrade potential, and Industry 4.0 readiness ensure longevity in evolving production landscapes.

Discover how the GV2040 can redefine your production capabilities. Explore detailed specifications and schedule a live demo today.