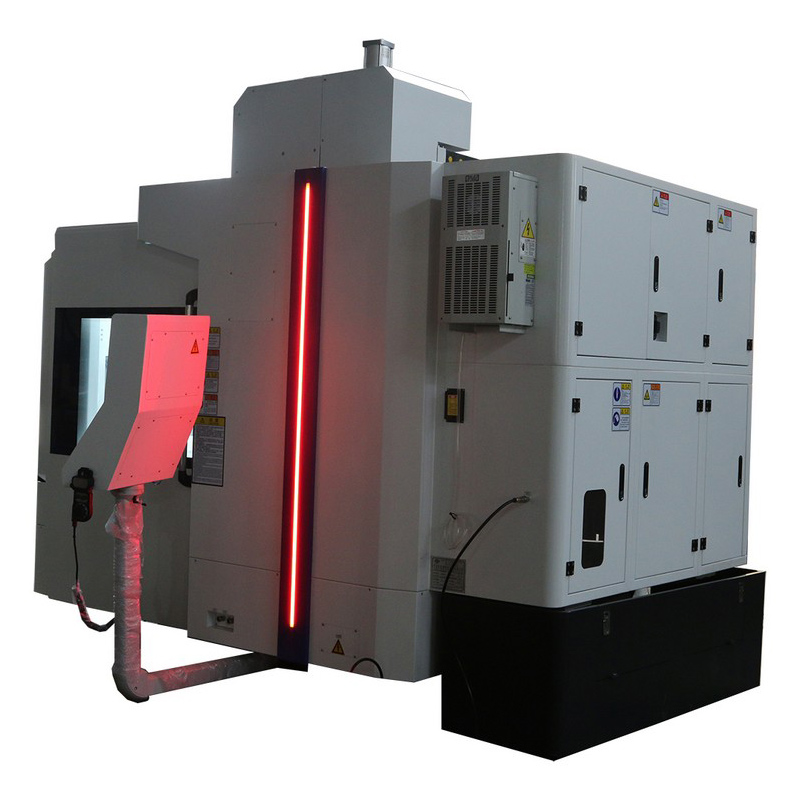

In the highly competitive automotive parts manufacturing industry, achieving high - speed heavy - duty machining with precision and stability is crucial. The DC1417 CNC milling machine emerges as a game - changer, offering a comprehensive solution to meet these demanding requirements.

Let's first understand the pain points of traditional equipment. Traditional milling machines often struggle with maintaining accuracy during high - speed operations. They may have an accuracy error of up to ±0.05mm, which can lead to a significant number of defective products. In terms of stability, continuous long - term operation can cause overheating, resulting in reduced machining quality and frequent breakdowns. Also, their processing speed is relatively slow, taking about 30 - 40 minutes to complete a complex automotive part.

The DC1417 is equipped with an advanced CNC system that enables precise control of every movement. It can achieve an accuracy error of only ±0.01mm, which is a huge improvement compared to traditional machines. This high precision ensures that each automotive part meets the strictest quality standards.

Regarding its power configuration, the DC1417 has a powerful spindle motor that provides a continuous power output of 15kW. This allows it to handle heavy - duty machining tasks with ease. It can cut through hard materials such as high - strength steel used in automotive parts without any significant slowdown.

Moreover, the DC1417 is specifically optimized for mold processing. Its unique design reduces vibration during operation, further enhancing stability. It can operate continuously for up to 24 hours a day without any major performance degradation, which is a significant advantage for mass - production automotive part manufacturers.

Let's take a look at some real - world examples. A well - known automotive parts manufacturer in Germany adopted the DC1417. Before using the DC1417, their production line had a processing speed of 20 parts per hour with a good product rate of about 85%. After implementing the DC1417, the processing speed increased to 35 parts per hour, a 75% increase. The good product rate also rose to 95%, which significantly reduced the cost of waste and rework.

| Features | Traditional Milling Machines | DC1417 CNC Milling Machine |

|---|---|---|

| Accuracy Error | ±0.05mm | ±0.01mm |

| Processing Speed | 20 parts per hour | 35 parts per hour |

| Continuous Operation Time | 8 - 12 hours | 24 hours |

| Good Product Rate | 85% | 95% |

As shown in the table, the DC1417 outperforms traditional machines in every aspect, making it an ideal choice for automotive parts manufacturers aiming for high - efficiency and high - quality production.

The DC1417 CNC milling machine is not just about speed; it's about delivering stable and precise results. It allows every cut to be precisely controlled, ensuring that your automotive parts manufacturing process is both efficient and of high quality. With the DC1417, your factory can stand out in the competitive market.

Are you ready to take your automotive parts manufacturing to the next level? Do you have any questions about how the DC1417 can fit into your production line? Leave your comments below and let's start a discussion.