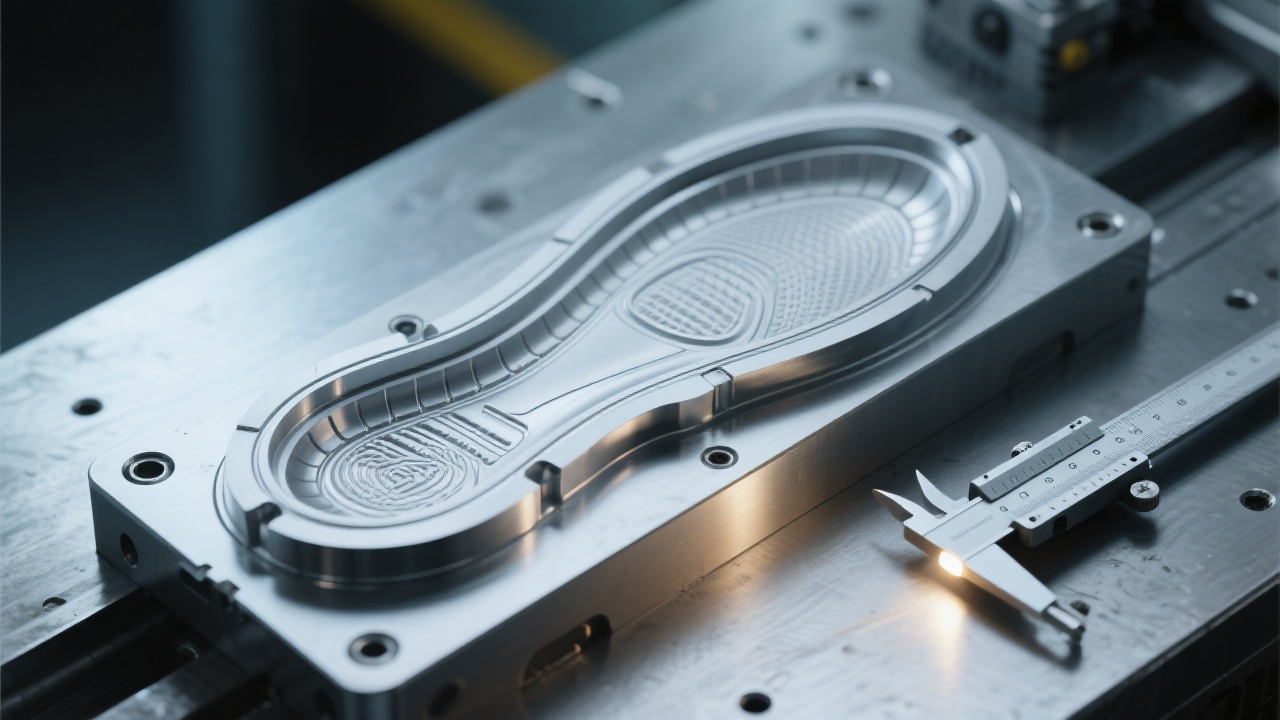

The FANUC GV2030 heavy-duty machining center finds wide applications in various industries such as the automotive and aerospace sectors. In the automotive industry, it is used for manufacturing engine components, transmission parts, etc. In aerospace, it plays a crucial role in fabricating high - precision parts like turbine blades. What makes the FANUC GV2030 stand out is its integration with the high - performance Fanuc controller.

The Fanuc controller offers an astonishing level of precision. It has a positioning error of just ±0.005mm. This high precision ensures that every cut and operation on the FANUC GV2030 is carried out with extreme accuracy, allowing for the production of parts with tight tolerances. Whether it's a complex automotive gear or a delicate aerospace component, the Fanuc controller can handle it with ease.

In addition to precision, long - term stability is another key feature. Through advanced algorithms and high - quality hardware, the Fanuc controller can maintain stable performance over long - term continuous operation. It has been tested to run for over 10,000 hours without significant degradation in performance, providing manufacturers with a reliable solution for their production needs.

| Performance Metrics | Traditional Controllers | Fanuc Controller |

|---|---|---|

| Speed | Slower, with an average operation speed of 50% of the Fanuc controller | Fast, enabling rapid tool changes and high - speed machining |

| Consistency | Poor, with variations in part quality from batch to batch | High, ensuring consistent part quality across large production runs |

| Failure Rate | High, approximately 10% per year | Low, less than 2% per year |

Let's take a look at a real - world example of a well - known automotive company that adopted the FANUC GV2030 with the Fanuc controller. Before the adoption, the company faced issues such as high次品率 and long production cycles. After implementing the new system, the results were remarkable. The良品率 increased by 15%, and the production cycle time was shortened by 20%. As the plant manager said, "The Fanuc controller on the FANUC GV2030 has truly transformed our production process. It allows us to produce high - quality parts at a much faster rate, giving us a significant competitive edge in the market."

From an enterprise perspective, the FANUC GV2030 with the Fanuc controller brings a multitude of benefits. Firstly, it helps in cost reduction and efficiency improvement. By reducing the次品率 and shortening the production cycle, the company can save on raw materials, labor, and energy costs. Secondly, it enhances the enterprise's market response ability. With faster production, the company can quickly respond to market demands and changing customer needs. Finally, it creates brand premium space. High - quality products produced by the FANUC GV2030 can enhance the company's brand image and reputation, allowing it to charge a premium for its products.

Let every cut be precise and drive your business growth with the FANUC GV2030 and Fanuc controller!