In the demanding world of large-scale mold manufacturing, precision is paramount. Manufacturers and machining workshops require CNC milling machines capable of delivering consistent, high-accuracy results that meet industry standards and customer expectations. The DC1520 CNC milling machine, featuring a robust gantry structure and advanced three-axis travel design, has become a benchmark for excellence in precision machining. This article delves into the technical standards of CNC milling machine precision, supported by real measured data from the DC1520, providing actionable insights for companies aiming to elevate their machining capabilities.

Large molds, often exceeding dimensions of 1.5 meters, impose stringent demands on machining precision due to complex geometries and functional tolerances, often within ±0.01 mm for critical features. Industry standards such as ISO 230-2 and ISO 10791 specify methodologies to evaluate these accuracies. Key parameters include:

Meeting such standards directly impacts product quality and operational costs by reducing rework and scrap rates.

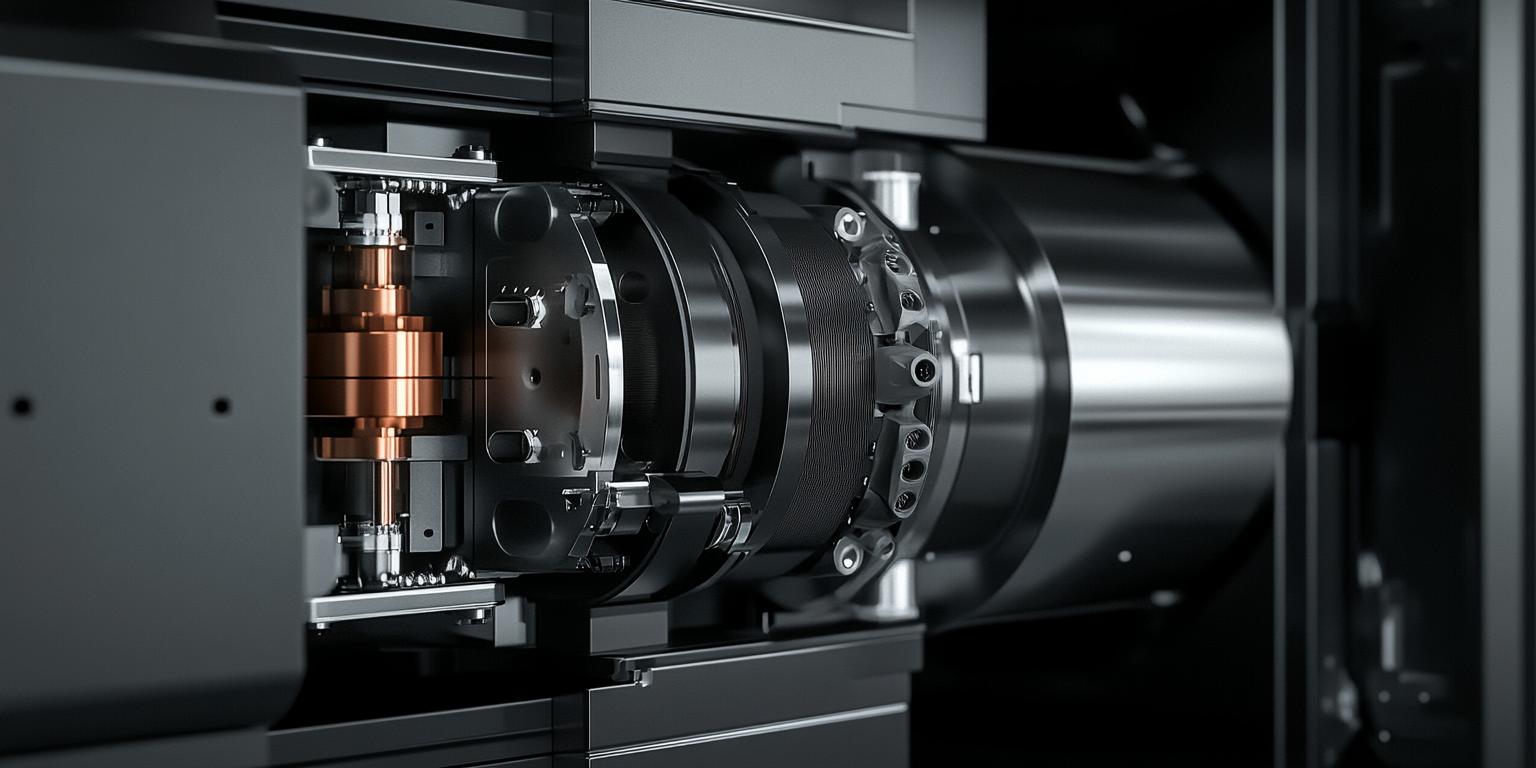

The DC1520 is engineered with a rigid gantry frame constructed from high-grade castings and stress-relieved steel, ensuring minimal deformation under load. Its design offers exceptional lateral stability, crucial when machining large molds with uneven cutting forces.

The machine features a substantial XYZ travel range of:

| Axis | Travel Range (mm) |

|---|---|

| X | 1500 |

| Y | 2000 |

| Z | 600 |

High rigidity ball screws and linear guides coupled with a closed-loop servo system guarantee positioning accuracy within ±0.006 mm and repeatability better than ±0.004 mm, verified under controlled ambient conditions.

Independent precision tests conducted per ISO 230-2 on the DC1520 reveal outstanding performance:

| Test Parameter | Measured Value | Industry Standard |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.006 / ±0.007 / ±0.005 mm | ±0.01 mm |

| Repeatability | ±0.004 mm | ±0.006 mm |

| Thermal Drift Over 8 Hours | < 5 µm | N/A |

A premier mold-making workshop in Germany reported a 20% alongside a 40% reduction in post-process corrections after integrating DC1520 into their production line. These improvements stemmed from the machine’s superior rigidity and repeatability, enabling tighter tolerances and reduced cycle times on molds sized up to 1800×2200 mm.

Compared to other gantry-type CNC milling machines in the same category, the DC1520 outperforms in areas such as:

This combination translates to lower downtime and consistent high-quality output for precision mold manufacturers.

The DC1520 incorporates several precision enhancement features such as:

These technologies ensure stable operations during extended cycles, crucial for large mold manufacturing where continuous precision is non-negotiable.

Have questions about CNC milling precision or want to see detailed performance reports? Leave your comments or contact us directly to receive tailored insights.