In the ever-evolving landscape of plastic mold manufacturing, the challenges in processing large-scale molds demand not only precision but also resilient machinery capable of reliable, heavy-duty operation. Selecting the right CNC milling equipment can dramatically impact production outcomes, cost-efficiency, and turnaround times. This article delves into the core advantages of the DC1317, a twin-column, heavy-duty CNC milling center specifically engineered to tackle the complexities of large plastic mold processing.

Large plastic mold machining often confronts issues such as maintaining processing accuracy over extended travels, controlling vibration in heavy parts, and ensuring consistent tool engagement with complex geometries. Customers processing molds larger than 1500 mm in any axis report problems including chatter marks, premature tool wear, and difficulty in achieving tight geometric tolerances below 0.02 mm.

To put it plainly, not every milling machine can sustain the stiffness and precision once the scale and weight of the mold exceed certain thresholds. Conventional milling centers often fall short in providing the necessary rigidity and travel capabilities, leading to compromised quality and frequent downtime.

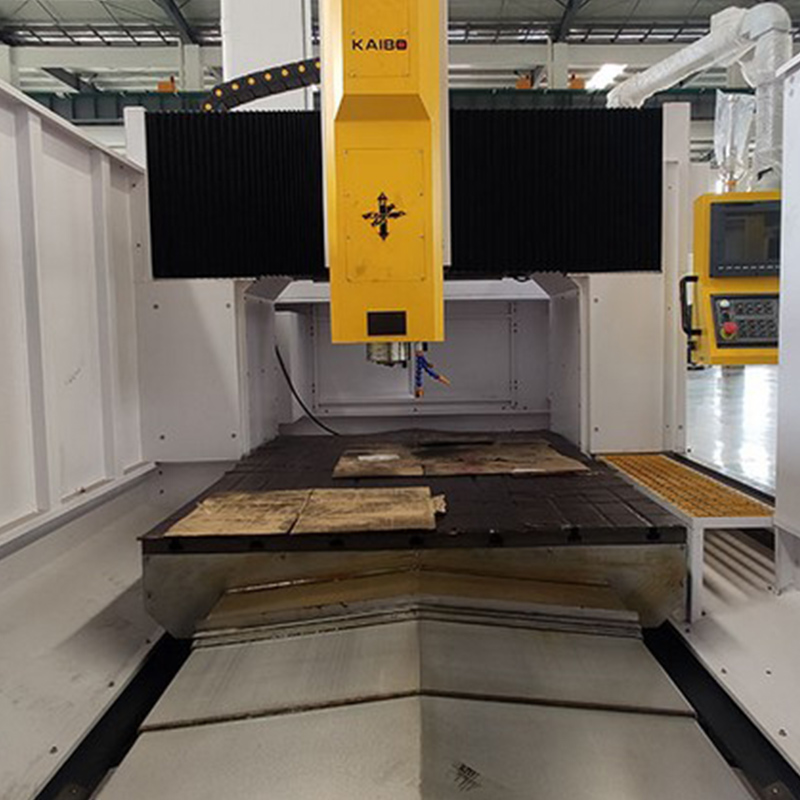

The DC1317 large heavy-duty CNC milling machine is built around a robust twin-column design featuring a high-rigidity machine bed fabricated from Meehanite cast iron with vibration-damping properties. This foundation ensures exceptional stability during long travel paths (up to 2000 mm in X, 1600 mm in Y, and 1200 mm in Z), crucial for large mold machining.

Its precision-ground linear guides coupled with a nonstop direct drive spindle and precision ball screws deliver smooth, backlash-free movement with positioning accuracy better than ±0.005 mm and repeatability within ±0.003 mm. This combination reduces machining deviations and improves surface finishes — vital for molds requiring mirror finishes or complex 3D contours.

| Feature | Technical Specification | Benefit |

|---|---|---|

| Twin-Column Structure | Meehanite cast iron, vibration-dampened chassis | Superior stability during heavy cutting, longer machine lifespan |

| Travel Range | X: 2000 mm, Y: 1600 mm, Z: 1200 mm | Supports large mold dimensions without repositioning |

| Spindle | Direct drive, 18 kW, 8,000 rpm max | High torque for tough materials, smooth surface finishes |

| Positioning Accuracy | ±0.005 mm, repeatability ±0.003 mm | Ensures tight tolerances critical for quality molds |

In a recent case study from a leading automotive component mold manufacturer in Germany, integrating the DC1317 into their production workflow led to a 25% reduction in cycle times when machining molds exceeding 1.8 meters. Precision improvements were confirmed through coordinate measuring machine (CMM) data, revealing a 40% decrease in dimensional deviations compared to previous equipment.

Another example involves a consumer electronics mold supplier in the United States, who reported a 35% increase in tool life and a 15% reduction in scrap rate after switching to the DC1317. The machine’s enhanced rigidity and smooth transmission minimized vibrations, preserving delicate tooling and delivering impeccable product quality.

When benchmarked against typical single-column or gantry mill models, the DC1317 excels in supporting heavier loads without structural flex. Traditional machines often struggle beyond 1000 mm travel due to decreased rigidity, causing compromises in tolerance and longer adjustment times.

Additionally, many competitors’ lower spindle power limits their ability to efficiently machine hardened steel molds common in modern plastics manufacturing. In contrast, the DC1317's 18 kW high-torque spindle drives through tough materials with stability and repeatability, directly impacting throughput and cost savings.

What are the core machining challenges your facility faces with large-scale molds? How do you currently address accuracy over long travel, and what improvements would significantly impact your production?

For enterprises seeking to elevate plastic mold machining through technology that merges power, precision, and durability, the DC1317 represents a compelling solution. Its engineering delivers measurable improvements in machining performance and operational efficiency — pivotal factors in maintaining competitive advantage.

Discover How DC1317 Can Transform Your Mold Production