In the large - scale plastic mold manufacturing industry, several persistent challenges have long hindered production efficiency and quality. Precision is a critical factor. In fact, statistics show that nearly 30% of large - scale mold production projects face issues with insufficient machining accuracy. This lack of precision often leads to a high rate of defective products, which can reach up to 15% in some cases, significantly increasing production costs.

Another major challenge is low production efficiency. Traditional machining methods can be extremely time - consuming, with some large - scale mold production processes taking weeks to complete. Moreover, the limited travel range of many conventional milling machines restricts the size of the molds that can be processed, preventing manufacturers from taking on larger and more complex projects.

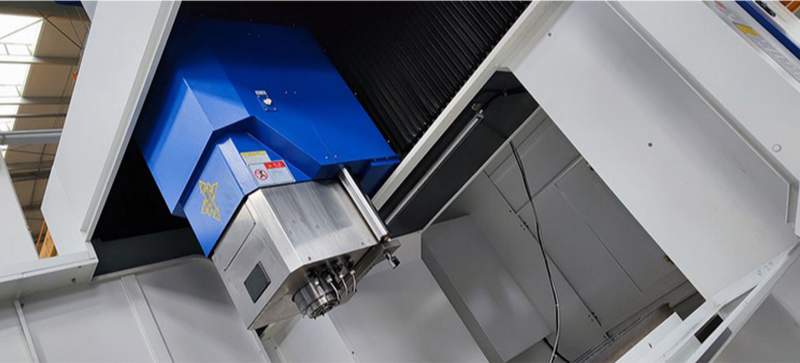

The DC1317 CNC milling machine, a large - scale double - column CNC milling center specifically designed for large and heavy plastic molds, is a game - changer in the industry. Its design philosophy is centered around solving the very problems that plague large - scale mold production.

The stability of its transmission system is one of its key selling points. Unlike traditional milling machines that may experience vibrations during operation, the DC1317's transmission system ensures smooth and consistent movement, much like a well - tuned engine in a high - performance car. This stability directly contributes to improved machining precision.

The high - rigidity body structure and heavyweight design of the DC1317 are also remarkable. With a high - rigidity body, the machine can withstand the large forces generated during the machining process, reducing deformation and ensuring long - term precision. The heavyweight of the machine, which can be up to [X] tons, further enhances its stability and damping performance, similar to a solid rock standing firm against the elements.

In addition, the large travel range of the DC1317 is a significant advantage. It can handle molds with much larger dimensions compared to its competitors, effectively eliminating the problem of limited travel range in large - scale mold production.

Let's look at some real - world data and case studies to understand the impact of the DC1317 CNC milling machine. One of our clients, a leading plastic mold manufacturer, was struggling with low production efficiency and high defect rates. After implementing the DC1317, they saw a remarkable improvement.

The machining efficiency increased by up to 40%. What used to take weeks to complete can now be finished in a matter of days. The defect rate dropped from 15% to less than 5%, resulting in significant cost savings. In terms of precision, the machining accuracy improved by [X]%, meeting the most stringent industry standards.

Our customers have been highly satisfied with the DC1317 CNC milling machine. One customer said, "The DC1317 has completely transformed our production process. It has solved all the problems we had with large - scale mold production. The precision and efficiency are truly outstanding." Another customer commented, "This machine has given us a competitive edge in the market. We can now take on larger and more complex projects with confidence."

The DC1317 CNC milling machine has proven to be a powerful tool for large - scale plastic mold production. It effectively addresses the common challenges in the industry, such as low efficiency, poor precision, and limited travel range. By using the DC1317, manufacturers can significantly improve the quality and efficiency of their mold production, achieving better results and higher profits.

DC1317 CNC milling machine helps large - scale mold production improve quality and efficiency. If you are looking to enhance your large - scale mold production capabilities, choose the DC1317 and achieve more efficient and high - quality large - scale mold processing. Click here to learn more about the DC1317 CNC milling machine and take the first step towards transforming your production process.