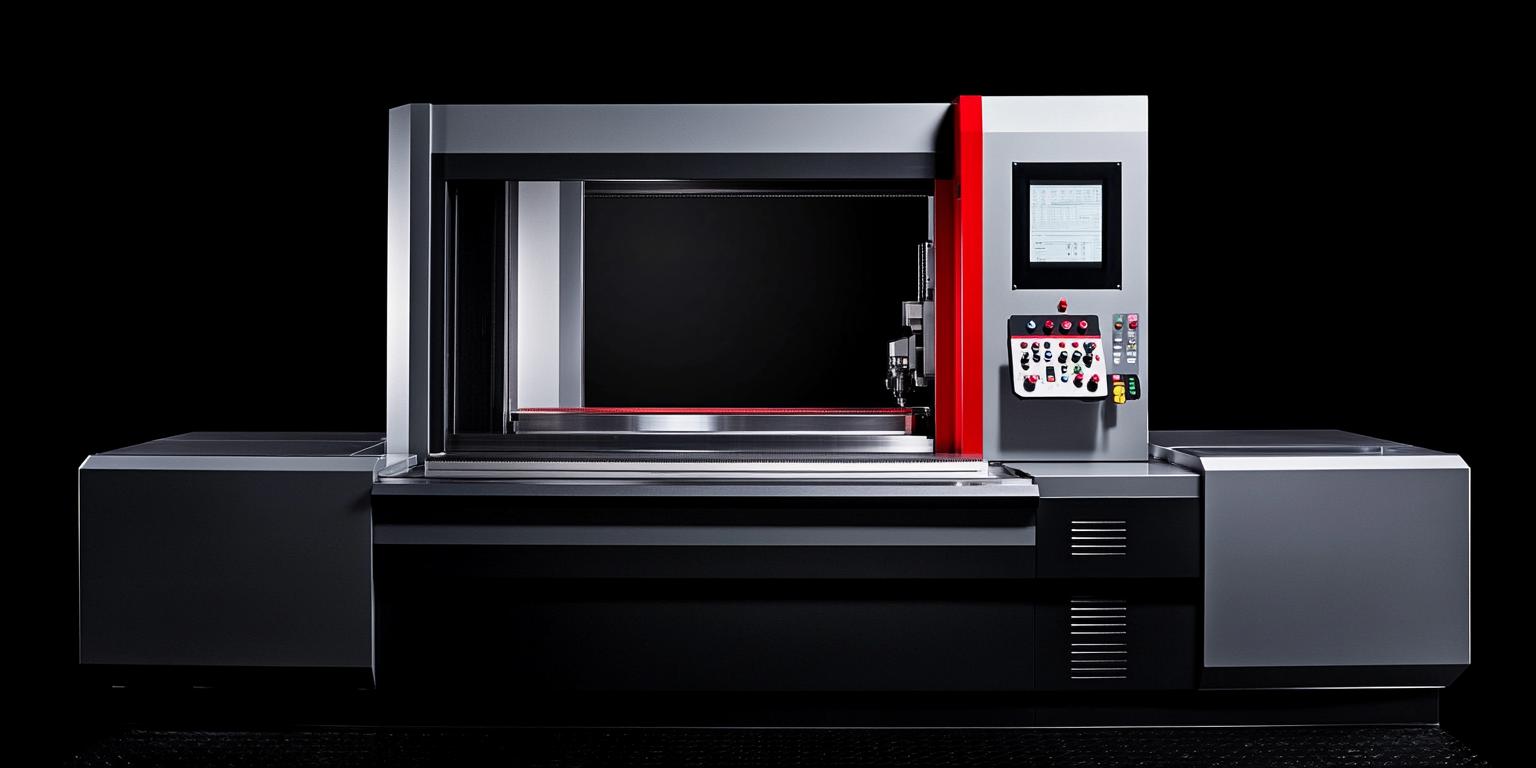

The DC1417 automotive parts CNC milling machine is a game - changer in the manufacturing industry. Specifically designed for medium - to large - sized molds and parts, it is a perfect fit for both automotive parts manufacturers and mold processing enterprises. In the highly competitive manufacturing landscape, where precision and efficiency are key, the DC1417 stands out as a reliable solution.

The heart of the DC1417 is its advanced CNC system. This system is engineered to maintain exceptional precision even at high - speed machining. With a positioning accuracy of up to ±0.005mm and a repeat positioning accuracy of ±0.003mm, it can handle the most intricate designs with ease. For example, when machining complex automotive engine parts, the high - speed operation of the DC1417, combined with its precise control, ensures that every detail is accurately reproduced. This not only improves the quality of the finished products but also significantly reduces the scrap rate. The high - speed interpolation function of the CNC system allows the machine to smoothly execute complex tool paths, enabling continuous and efficient production.

The power system of the DC1417 is a robust force behind its heavy - cutting capabilities. It is equipped with a high - torque spindle motor that can deliver a maximum power of 30kW. This powerful motor provides the necessary strength to cut through tough materials such as hardened steel and cast iron. In heavy - cutting operations, the DC1417 can maintain a stable cutting speed of up to 6000 RPM, ensuring efficient material removal. The rigid structure of the machine, combined with the powerful power system, also reduces vibration during the cutting process, further enhancing the surface finish of the machined parts. Say goodbye to the frustration of slow and inefficient heavy - cutting operations with the DC1417.

Let's take a look at some real - world applications. A well - known automotive parts manufacturer was facing challenges in meeting the increasing production demands while maintaining high quality. After installing the DC1417, they saw a remarkable improvement. The production efficiency increased by 30%, and the defect rate decreased from 5% to less than 1%. In another case, a mold processing company was struggling with the long - lead times for large - scale mold production. The DC1417 enabled them to reduce the production cycle by 25%, thanks to its high - speed and accurate machining capabilities. These data clearly demonstrate the outstanding performance of the DC1417 in real - world manufacturing scenarios.

The DC1417 offers significant value in terms of long - term production stability and cost control. Its stable and durable structure reduces the need for frequent maintenance, minimizing downtime. The high - precision machining also reduces the consumption of raw materials due to fewer rejects. Over time, these factors contribute to substantial cost savings. Moreover, the ability to achieve high - volume and high - quality production allows businesses to gain a competitive edge in the market. Let the DC1417 make your production line more stable and efficient, and help you achieve long - term success in the manufacturing industry.

Are you ready to take your manufacturing to the next level with the DC1417 automotive parts CNC milling machine? Click here to learn more and transform your production process today!