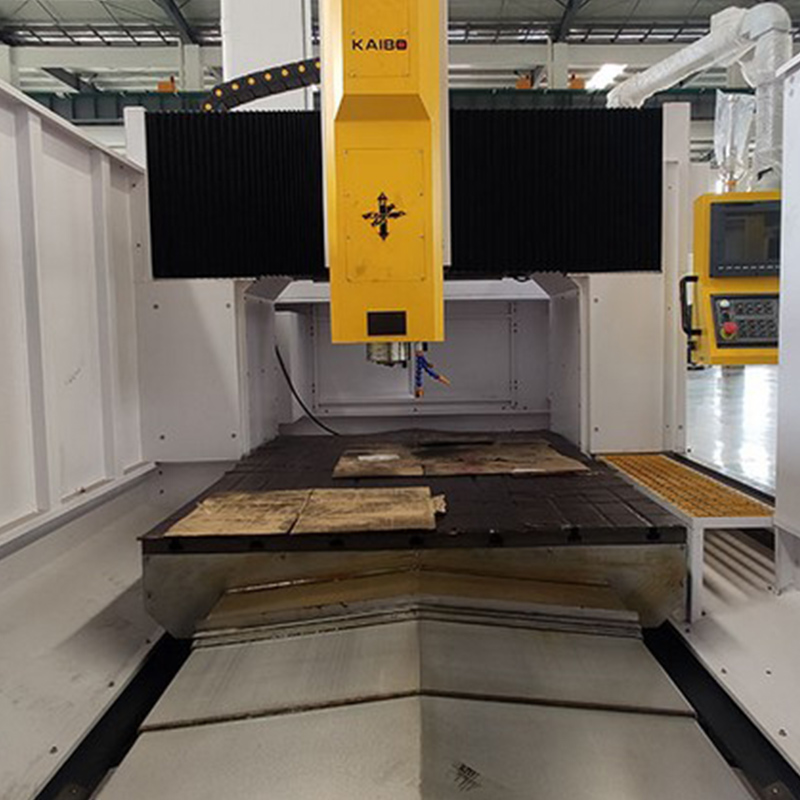

When it comes to precision manufacturing in the automotive and industrial sectors, choosing the right CNC milling machine isn’t just about power—it’s about stability, repeatability, and long-term ROI. For medium-to-large mold processing, one model consistently outperforms competitors: the DC1417 High-Stability龙门 (Gantry) CNC Milling Machine.

Unlike traditional column-type machines, the DC1417 features a full gantry structure that provides superior rigidity—especially critical when handling molds over 1,200 kg. According to real-world data from a Tier-1 supplier in Germany, this design reduces vibration by up to 40% during high-speed heavy cutting (at 150 m/min feed rate), resulting in surface finish improvements from Ra 3.2 μm to Ra 1.6 μm.

This structural advantage translates directly into production gains: users report an average of 25–30% reduction in cycle time per part compared to older models with fixed-column frames.

| Feature | Standard Column Type | DC1417 Gantry Type |

|---|---|---|

| Max Load Capacity | 800 kg | 1,500 kg |

| Vibration Damping | Low (Ra > 3.2 μm) | High (Ra ≤ 1.6 μm) |

| Cycle Time Reduction | ~10% | 25–30% |

A major mold manufacturer in Mexico upgraded from a conventional 5-axis mill to the DC1417 last year. Their feedback? “We saw immediate improvements—not just in accuracy but also in tool life. Our end mills lasted 40% longer because there was less deflection.”

Another user in South Korea reported saving over $12,000 annually in scrap material costs after switching to the DC1417, thanks to consistent dimensional control across batches—even for complex cavity inserts.

While many machines claim "high rigidity," few deliver measurable results under continuous heavy-duty conditions. The DC1417 combines:

These aren't just specs—they’re what keep your team productive, reduce downtime, and ensure every molded part meets ISO 2768 standards without rework.

If you're investing in medium-to-large mold production, don’t settle for generic solutions. The DC1417 isn’t just another CNC mill—it’s a performance-driven platform built for durability, speed, and consistency.

Discover how the DC1417 can transform your workflow—from setup to final output—with unmatched stability and efficiency.

Explore DC1417 Technical Specifications →