In the realm of automotive parts manufacturing, the pursuit of high - speed and high - precision machining has always been a core challenge. The DC1417 CNC milling machine emerges as a remarkable solution, leveraging advanced CNC systems to ensure exceptional precision during high - speed processing. This article delves deep into how the DC1417's CNC system supports stability and accuracy in high - speed machining.

The CNC system of the DC1417 plays a crucial role in precisely regulating the feed rate, acceleration and deceleration response, and path smoothness. For instance, it can adjust the feed rate up to 20 meters per minute, which significantly shortens the processing time. Moreover, the acceleration and deceleration response time is within 0.5 seconds, allowing for rapid and stable transitions between different machining states. This ensures that the tool can quickly adapt to changes in the machining path, reducing errors caused by inertia.

The path smoothness is another key aspect. The CNC system uses advanced interpolation algorithms to ensure that the tool moves along a smooth path, even when machining complex curves. This results in a surface finish with a roughness of Ra 0.8μm, which meets the high - precision requirements of automotive parts.

Let's take the complex surface milling as an example. When machining a mold with complex free - form surfaces, the DC1417 can maintain a positioning accuracy of ±0.01mm. This high level of accuracy is achieved through real - time error compensation. The CNC system continuously monitors the position and status of the tool and makes adjustments in real - time to correct any deviations. This ability to maintain accuracy in complex scenarios makes the DC1417 an ideal choice for manufacturers dealing with high - precision parts.

Compared with traditional control systems, the DC1417's CNC system offers significant advantages in terms of先进性 and reliability. Traditional systems often have limited processing capabilities and are prone to errors in high - speed and complex machining scenarios. In contrast, the DC1417's system can handle large - scale data processing in real - time, ensuring stable and accurate operation. For example, in a long - term continuous machining test, the DC1417 maintained an accuracy stability rate of over 98%, while traditional systems only achieved about 90%.

To further prove its effectiveness, let's look at some customer cases. A well - known automotive parts manufacturer used the DC1417 for mass - production of engine components. After six months of operation, they reported a 30% increase in production efficiency and a 50% reduction in scrap rate. These data clearly demonstrate that the DC1417 can provide reliable and efficient production solutions for manufacturers.

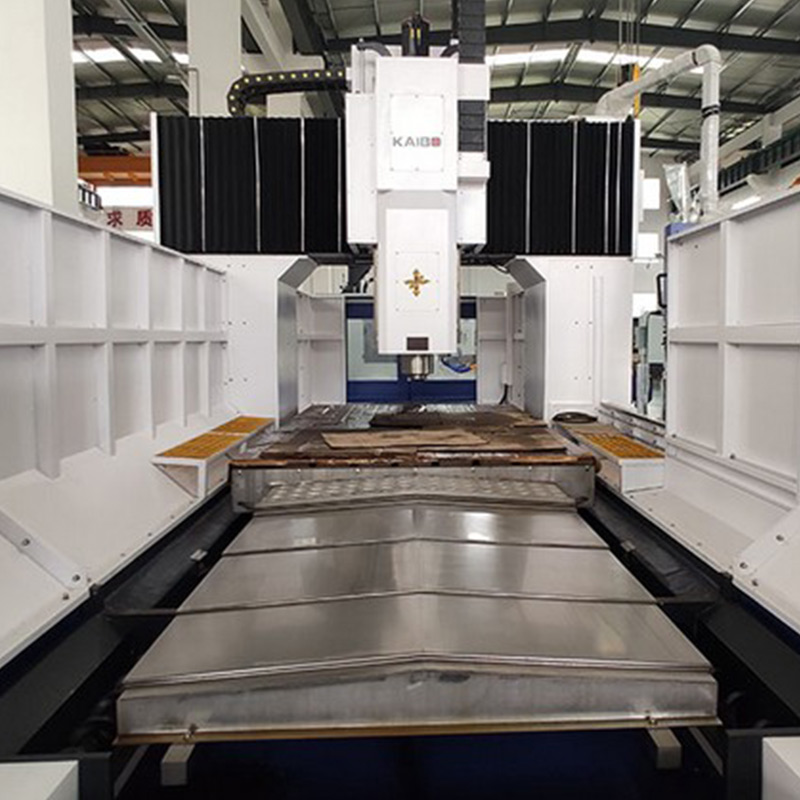

The DC1417's structural design works in harmony with the CNC system to enhance the overall performance. The rigid gantry structure provides a stable foundation for high - speed machining, reducing vibrations and ensuring the accuracy of the tool's movement. The combination of the advanced CNC system and the robust structure allows the DC1417 to offer a comprehensive solution for high - precision automotive parts manufacturing, providing long - term stability for mass - production.

In conclusion, the DC1417 CNC milling machine, with its advanced CNC system, offers manufacturers a reliable way to achieve high - speed and high - precision machining. It can make every high - speed cutting precise and inject stable power into your mass - production. If you are looking for a high - performance milling machine to ensure the long - term stable production of your enterprise, the DC1417 is definitely worth considering. Do you have any questions or experiences about high - precision milling machines? Feel free to leave a comment below.