In the realm of large-scale mold manufacturing, achieving high dimensional accuracy while maintaining operational efficiency has historically posed significant challenges for many workshops. The DC1520 CNC milling machine introduces a game-changing advancement addressing these core concerns through its robust design and precision-engineered components. Tailored exclusively for the demands of large molds, the DC1520 stands out by marrying high rigidity with expansive three-axis travel, resulting in measurable productivity gains and superior surface finishes.

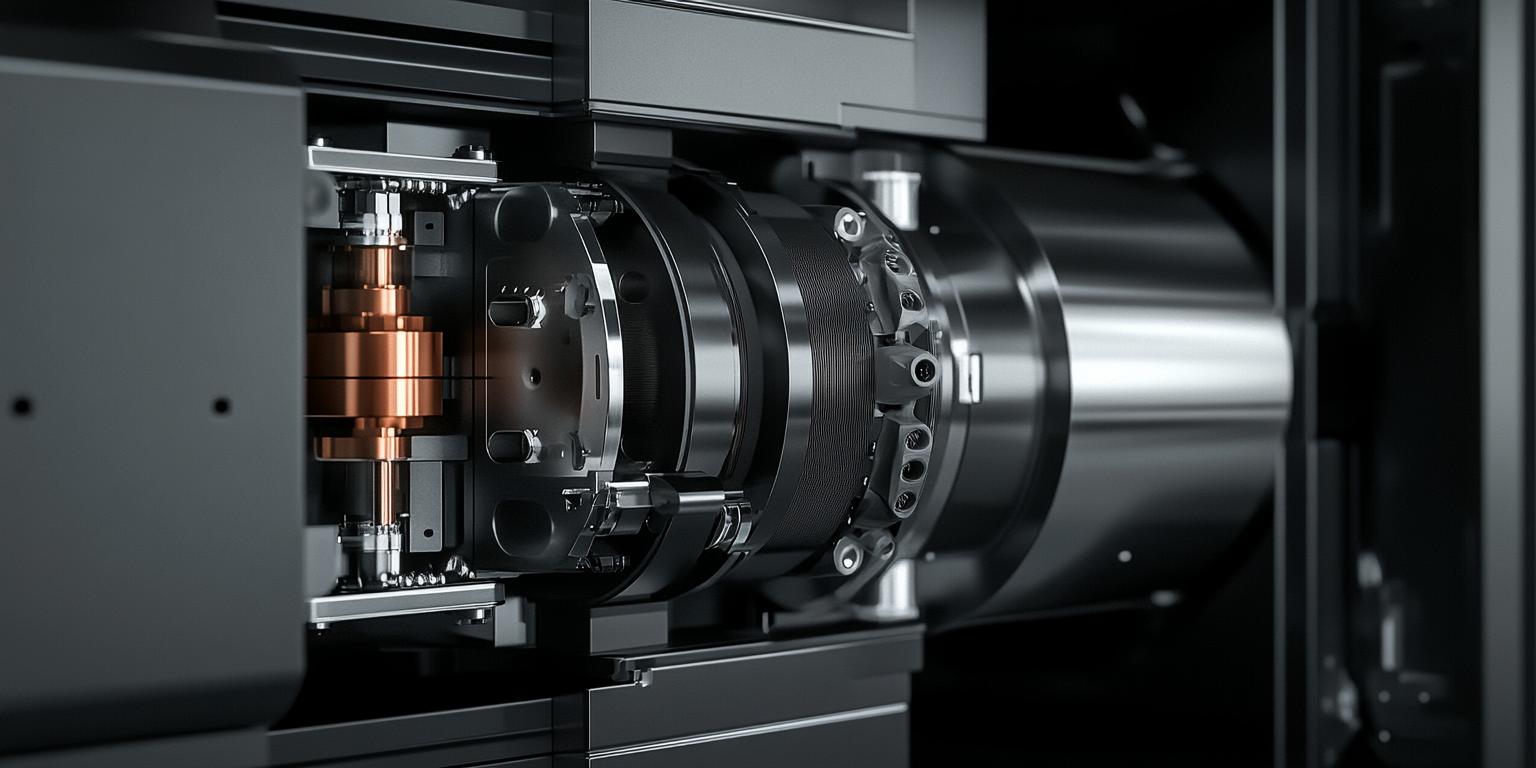

At the heart of the DC1520 lies a gantry-type architecture, meticulously crafted to withstand heavy cutting forces without compromising accuracy. The gantry framework minimizes vibration and deflection, crucial factors when machining molds exceeding 1500mm in length. This structural design directly supports consistent tool paths, enabling precision within ±0.01 mm tolerance over the entire working envelope.

The machine's three-axis travel span of 1500mm x 2000mm x 720mm provides unparalleled flexibility, accommodating an extensive range of large mold dimensions. This wide travel capacity reduces the need for repositioning workpieces, thus cutting cycle times and minimizing cumulative errors.

| Parameter | Traditional Milling Machines | DC1520 CNC Milling Machine |

|---|---|---|

| Machining Tolerance | ±0.05 mm | ±0.01 mm |

| Typical Cycle Time for Large Mold | 48 - 60 hours | 35 - 42 hours |

| Surface Finish Quality (Ra µm) | 1.6 - 3.2 | 0.8 - 1.2 |

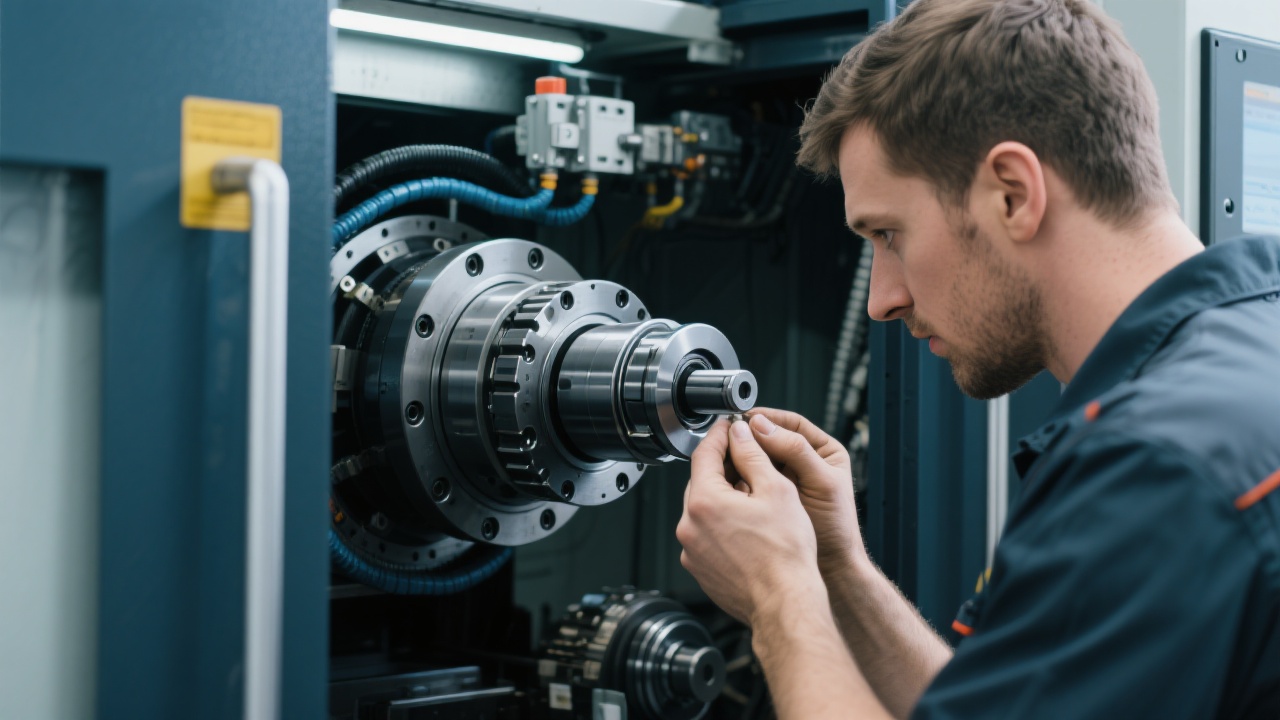

Mold Maker Inc., a leading manufacturer specializing in automotive molds, implemented the DC1520 CNC mill last year. Prior to integration, their production suffered frequent delays due to insufficient machine rigidity and limited workpiece size capacity, often requiring multiple setups.

After installing the DC1520, the company reported a:

These enhancements led to faster delivery schedules and higher client satisfaction, affirming the DC1520’s role in boosting competitive advantage.

Conventional large mold machining often encounters:

The DC1520’s reinforced gantry framework and generous axis travel inherently resolve these issues, significantly minimizing error accumulation and enhancing surface integrity.

Beyond technical superiority, the DC1520 offers:

Have questions on specific mold sizes, material compatibility, or throughput expectations? We invite you to join the conversation. Share your challenges or inquire about how the DC1520 can revolutionize your mold machining workflow.