In the realm of large-size mold production, manufacturers often face persistent challenges such as inconsistent machining accuracy and low operational efficiency. These issues directly impact production timelines, product quality, and ultimately market competitiveness. The introduction of the DC1520 CNC milling machine has offered a breakthrough solution to these hurdles, setting a new standard for precision and productivity in mold manufacturing.

Large-size molds require machining equipment capable of handling extensive parts with tight tolerances. Fabricators have traditionally grappled with:

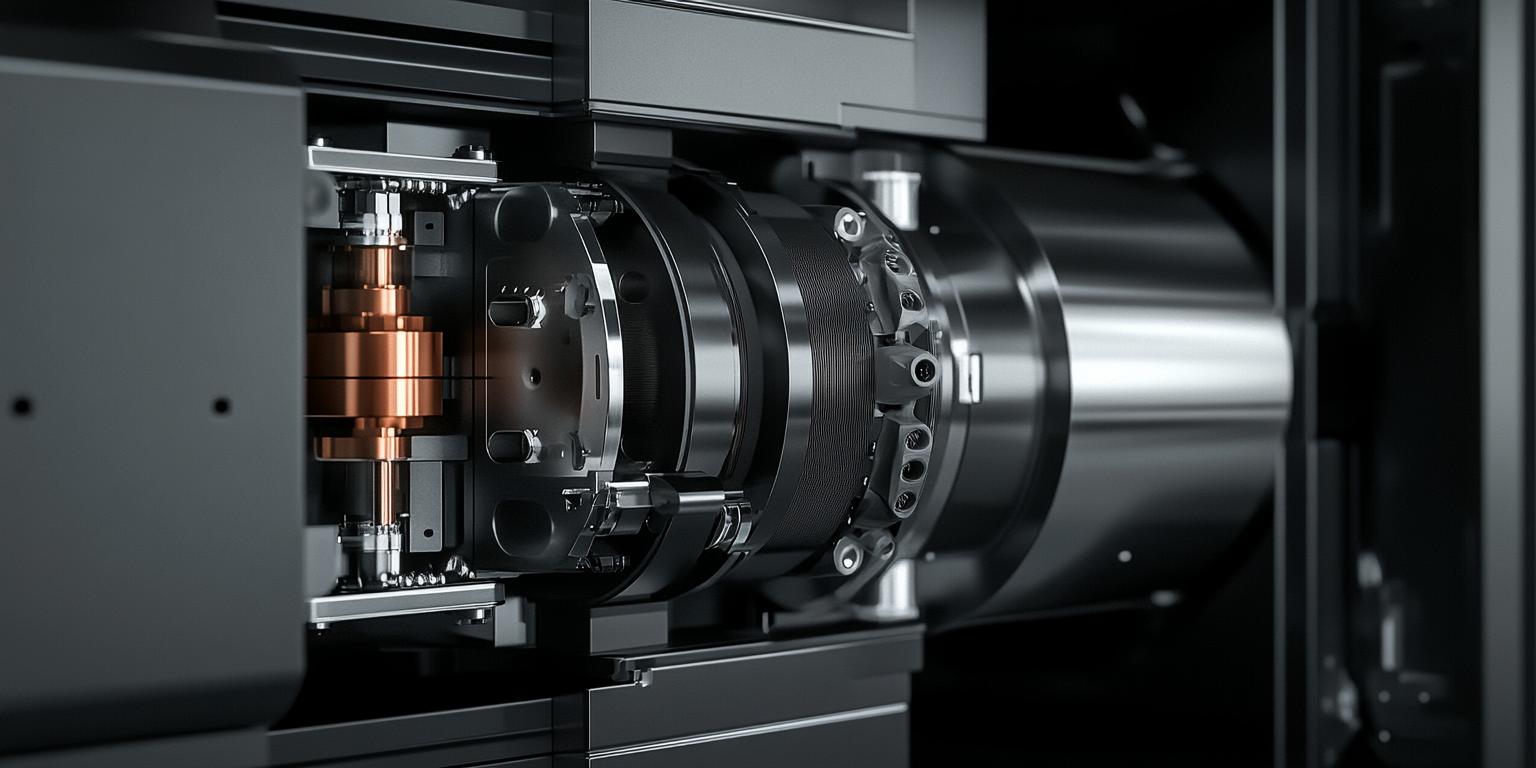

The DC1520 was engineered to directly address these challenges through an innovative combination of structural design and advanced control technology.

| Feature | Specification/Benefit |

|---|---|

| Structural Design | Robust Gantry (Portal) Structure ensuring exceptional rigidity and minimal vibration during heavy-duty milling |

| Working Range | X: 1500 mm × Y: 2000 mm × Z: 720 mm—ideal for large mold components and multi-axis operations |

| Precision Control | Achieves machining accuracy within ±0.01 mm, exceeding industry standards for mold manufacturing |

| Maintenance Efficiency | Designed for ease of maintenance, reducing downtime and overall operational costs |

These specifications translate into reliable performance, allowing manufacturers to achieve consistently high-quality output with reduced rework rates.

“Since integrating the DC1520 into our production line, our good product rate jumped to 98%, and we cut our delivery time by nearly 30%. The machine’s stability and precision gave us renewed confidence to tackle complex mold designs.” — Production Manager, Precision Moldworks Ltd.

The Precision Moldworks case exemplifies how the DC1520 enables manufacturers to:

When benchmarked against competing CNC milling machines, the DC1520 consistently excels in:

| Criteria | DC1520 | Typical Competitor |

|---|---|---|

| Structural Rigidity | High (Gantry design with reinforced beams) | Moderate (Smaller frames prone to vibration) |

| Maintenance Cost | Lower due to modular components & accessible design | Higher, complex setups lead to longer downtime |

| Suitability for Complex Curves | Superior (High-precision control with multi-axis adaptability) | Limited by machine stability and control precision |

This differentiation positions the DC1520 as the preferred machine for mold manufacturers striving for precision, efficiency, and cost-effectiveness.

By adopting the DC1520, enterprises gain a powerful advantage in reducing operational expenses and scaling production capacity. Key benefits include: