Large - scale mold processing has always been a challenging task in the manufacturing industry. Precision control and equipment stability are two major hurdles that mold enterprises often face. Traditional CNC milling machines, due to their structural limitations, struggle to meet the high - precision and large - scale processing requirements of modern mold manufacturing. However, the high - precision CNC milling machine DC1520 offers a breakthrough solution.

When it comes to large - scale mold processing, precision control is extremely difficult. Even a small deviation can lead to the rejection of the entire mold, resulting in increased production costs. Moreover, traditional equipment often suffers from poor stability, which can cause vibration during long - term operation, further affecting the processing accuracy. These issues not only reduce production efficiency but also limit the competitiveness of mold enterprises in the market.

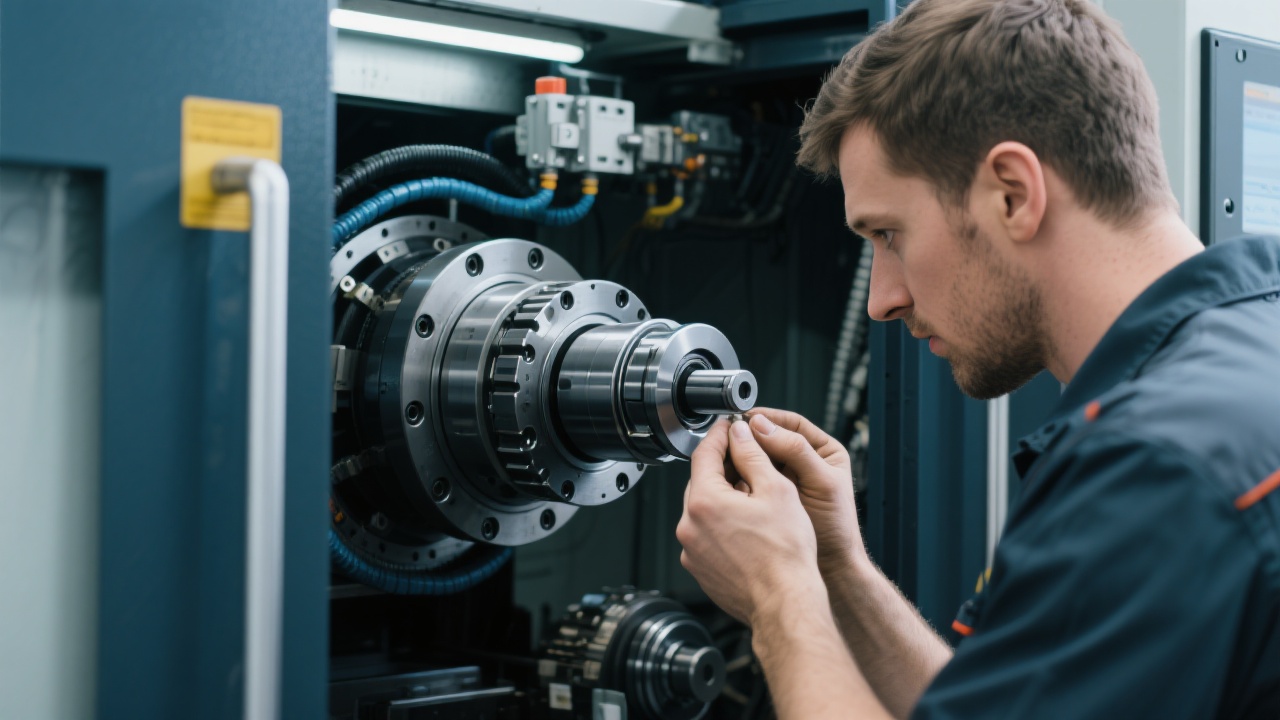

The DC1520 is specifically designed for large - scale mold processing. It features a gantry structure, which provides excellent stability and support. With a three - axis travel of 1500*2000*720mm, it can easily handle large - sized workpieces. The high - rigidity design ensures that the machine can maintain its shape and performance even under heavy loads. The precision positioning system allows for accurate control of the tool path, achieving a processing accuracy of ±0.01mm.

To better understand the advantages of DC1520, let's compare it with similar products in the market. The following table shows the performance comparison:

| Features | DC1520 | Similar Products |

|---|---|---|

| Processing Accuracy | ±0.01mm | ±0.02 - 0.03mm |

| Load Capacity | High (suitable for large - scale molds) | Medium |

| Long - term Stability | Excellent (less vibration) | Good |

As shown in the table, DC1520 outperforms similar products in terms of processing accuracy, load capacity, and long - term stability. Its high - precision processing ability ensures that the molds produced meet the strictest quality requirements, while its large load capacity allows it to handle more complex and larger - sized molds.

Let's take a look at some real - world customer cases to see the actual application effects of DC1520. A well - known automotive mold factory introduced the DC1520 into its production line. After using the machine for a period of time, the factory saw a significant improvement in its production efficiency. The good product rate increased by 15%, and the production cycle was shortened by 20%. This not only reduced the production cost but also enhanced the factory's market competitiveness.

By choosing DC1520, mold enterprises can enjoy multiple benefits. Firstly, it can significantly improve production efficiency. The high - speed processing and accurate positioning capabilities of DC1520 allow for faster mold production. Secondly, it can reduce the scrap rate. The high - precision processing ensures that the molds produced are of high quality, reducing the number of defective products. Finally, it can enhance market competitiveness. With higher - quality products and faster delivery times, enterprises can gain an edge in the market.

Do you also face similar challenges in your mold processing? If so, the DC1520 is the ideal solution for you. It can make complex mold processing simple and efficient, and its hard - core strength will surely win your trust. Don't miss this opportunity to take your mold processing to the next level!