In the realm of large-scale mold production, manufacturers often grapple with a series of daunting challenges. Precision is a critical aspect, yet many existing machines struggle to achieve the required accuracy, leading to sub - standard products. Efficiency is another major concern. Outdated equipment can cause long processing times, which not only increases production costs but also delays delivery schedules. Moreover, the inability to perform full - size machining of complex molds is a significant pain point. This limitation restricts the design and production of large and intricate molds, hindering the growth and innovation of the industry.

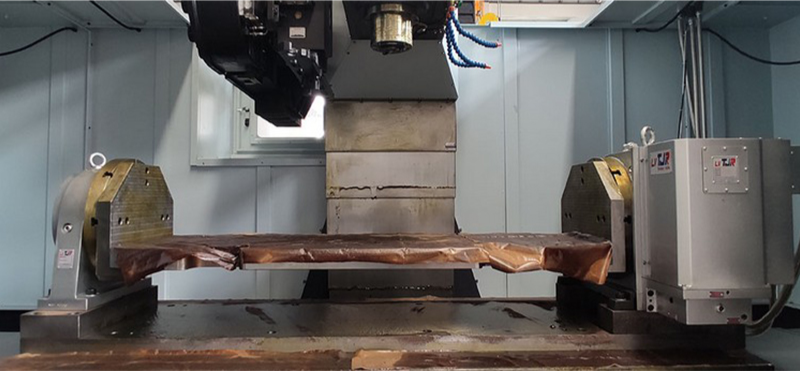

The DC1317 large double - column CNC milling center emerges as a reliable solution to these challenges. One of its core advantages is the smooth transmission system. This feature enables the machine to operate continuously and efficiently. Unlike some traditional machines that may experience jitters or slowdowns during operation, the DC1317 maintains a stable and fast - paced workflow, ensuring that large - scale mold production can proceed without interruption.

The high - rigidity and heavy - duty机身 of the DC1317 play a crucial role in maintaining precision. The robust structure effectively resists vibrations and external forces, providing a stable platform for machining. This results in consistent precision throughout the entire machining process, regardless of the complexity of the mold. Even for large - scale and high - precision molds, the DC1317 can achieve the required accuracy, reducing the rate of defective products.

Another remarkable feature is the large stroke. With an extended stroke, the DC1317 can cover complex mold structures. It can reach every corner of the mold, enabling full - size machining. This eliminates the need for multiple setups and re - positioning, which not only saves time but also improves the overall quality of the mold.

The performance improvement brought by the DC1317 is not just theoretical. In real - world applications, it has demonstrated significant results. For example, in a case study of a large - scale mold manufacturing company, after adopting the DC1317, the processing time was shortened by 30%. This means that the company can produce more molds in the same amount of time, increasing its production capacity and competitiveness in the market.

The reduction in the defective product rate is also remarkable. Before using the DC1317, the defective product rate of the company was around 5%. After the implementation of the DC1317, the defective product rate dropped to less than 1%. This not only saves costs associated with waste and re - work but also enhances the company's reputation for quality.

To further validate the effectiveness of the DC1317, let's hear from some of its satisfied customers.

"The DC1317 has completely transformed our mold production process. Its efficiency and precision are unparalleled. We used to struggle with long lead times and high defect rates, but since we started using the DC1317, our production has become much more streamlined, and our customers are extremely satisfied with the quality of our molds." - John Smith, CEO of a leading mold manufacturing company.

These testimonials reflect the trust and recognition that the DC1317 has gained in the industry. It has become a reliable choice for many companies looking to improve their large - scale mold production capabilities.

If you are still facing challenges in large - scale mold production, the DC1317 large double - column CNC milling center is the solution you've been waiting for. Its efficient, precise, and reliable performance can significantly enhance your production efficiency and product quality. Don't miss out on this opportunity to revolutionize your mold production process. Click here to learn more about the DC1317 and take the first step towards a more successful mold manufacturing business.