When it comes to high - speed and heavy - duty machining in the automotive parts manufacturing industry, the DC1417 CNC milling machine stands out. Let's delve into its core technical advantages. First, the precision control of its CNC system is remarkable. With advanced algorithms and real - time monitoring, it can achieve an accuracy control within ±0.01mm, ensuring that each cut is precise and efficient. This high - precision control significantly reduces the error rate in the machining process, leading to higher - quality products.

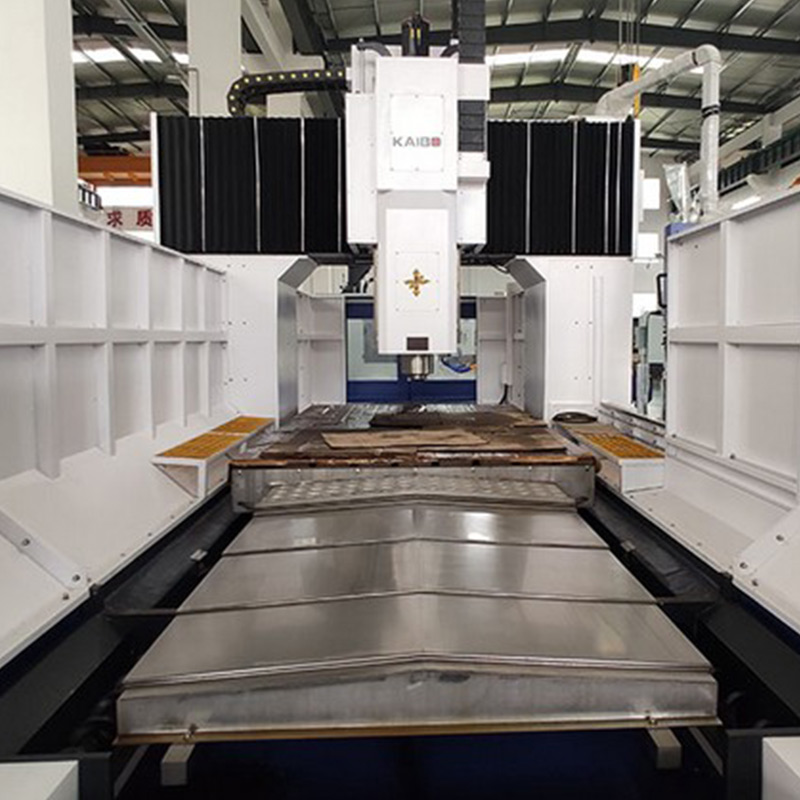

The spindle of the DC1417 has a powerful power output capacity. It can reach a maximum power of 30kW, enabling it to handle high - speed and heavy - load machining tasks. For example, when processing large - scale automotive parts, the high - power spindle can maintain a stable rotation speed, which is crucial for ensuring the smooth progress of the machining process. In addition, the structural rigidity design of the DC1417 is also a highlight. Its unique gantry structure and high - strength materials make it have excellent stability during high - speed operation, reducing vibration and ensuring the accuracy of the machining results.

Let's take a look at some typical customer application scenarios. In the processing of engine cylinder blocks, traditional milling machines often face problems such as low efficiency and poor surface finish. However, the DC1417 can increase the processing efficiency by up to 30%. In a real - world case, a customer used to take 8 hours to process an engine cylinder block with a traditional milling machine. After switching to the DC1417, the processing time was reduced to 5.6 hours. At the same time, the surface roughness of the processed cylinder block was reduced from Ra6.3 to Ra3.2, greatly improving the quality of the product.

For the processing of transmission cases, the DC1417 also shows excellent performance. It can ensure high - precision machining of complex internal structures, improving the assembly accuracy of the transmission. In a customer's factory, the rejection rate of transmission cases processed by the DC1417 was reduced from 5% to 1%, which not only saved production costs but also improved the overall competitiveness of the enterprise.

Traditional milling machines often have many pain points. For example, they are prone to overheating and mechanical wear during continuous high - intensity operations, resulting in frequent breakdowns and high maintenance costs. In contrast, the DC1417 has excellent reliability. It can operate continuously for more than 20 hours a day without significant performance degradation. According to statistics, the maintenance cost of the DC1417 is 40% lower than that of traditional milling machines in a one - year operation cycle. This is mainly due to its advanced cooling system and high - quality components, which effectively extend the service life of the equipment.

To further enhance the credibility of the DC1417, we have collected a large amount of user feedback and third - party verification data. A user from a well - known automotive parts manufacturing enterprise said: "Since we introduced the DC1417, our production efficiency has been significantly improved, and the quality of our products has also been greatly enhanced. It has become an indispensable part of our production line." Third - party testing institutions have also verified the performance of the DC1417. Their reports show that the DC1417 meets or even exceeds the industry standards in terms of processing accuracy, efficiency, and reliability.

If you are still struggling with low - efficiency and high - cost milling machines, it's time to make a change. The DC1417 CNC milling machine can provide you with a precise and efficient machining solution. Don't miss this opportunity to improve your production efficiency and product quality. Click here to learn more about the complete case set or book a on - site demonstration!

What processing bottleneck does your factory want to solve the most? Share your thoughts with us!