In the realm of large - scale mold manufacturing, efficiency, precision, and reliability are the cornerstones of success. However, many manufacturers often encounter a series of challenges, such as interrupted processing, insufficient precision, and difficulties in handling large - scale workpieces. These issues not only lead to increased production costs but also significantly reduce competitiveness in the market. Fortunately, the DC1317 large - scale double - column CNC milling machine emerges as a powerful solution to these long - standing problems.

Let's first take a look at the common pain points faced by manufacturers. Interrupted processing is a major headache. Traditional milling machines may experience frequent stops during the processing of large molds, which not only wastes time but also affects the overall quality of the product. In addition, insufficient precision can lead to high rejection rates, increasing production costs. When it comes to handling large - scale workpieces, many ordinary machines simply cannot meet the requirements, resulting in incomplete or inaccurate molding.

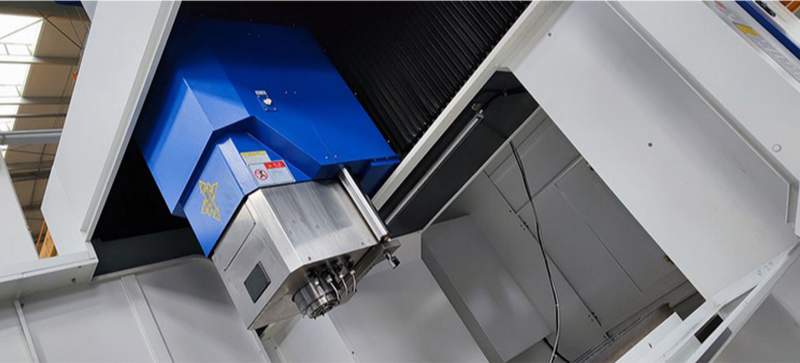

The DC1317 is designed with a double - column structure and a heavy - duty body, which provides excellent stability. This stability is crucial for continuous and precise processing. Even when dealing with large and heavy molds, the machine can maintain a high level of accuracy. The smooth transmission system of the DC1317 ensures continuous operation. It minimizes the risk of processing interruptions, allowing manufacturers to complete their tasks without unnecessary delays. Moreover, the large stroke design of the DC1317 enables the processing of large - scale workpieces in one go, eliminating the need for multiple setups and reducing the chances of errors.

To better understand the advantages of the DC1317, let's compare it with ordinary equipment. In terms of precision, ordinary milling machines may have an error range of around ±0.05mm, while the DC1317 can achieve an error range of ±0.01mm, providing a much higher level of accuracy. When it comes to speed, the DC1317 can complete a large - scale mold processing task in 6 hours on average, while ordinary machines may take up to 10 hours. In terms of reliability, the DC1317 has a much lower failure rate, reducing the downtime for maintenance and repair.

| Parameters | Ordinary Equipment | DC1317 |

|---|---|---|

| Precision (Error Range) | ±0.05mm | ±0.01mm |

| Processing Time for Large - scale Molds | 10 hours | 6 hours |

| Failure Rate | 15% | 3% |

In actual applications, the DC1317 has shown remarkable results. According to statistics, manufacturers using the DC1317 have achieved a production efficiency improvement of over 30%. This means that they can produce more products in the same amount of time, increasing their overall output. At the same time, the rejection rate has decreased by 40%, which directly reduces production costs and improves product quality. These data clearly demonstrate the effectiveness of the DC1317 in solving large - scale mold production problems.

Don't just take our word for it. Here are some real - world testimonials from our satisfied customers. "Since we introduced the DC1317, our production process has become much more efficient. We no longer have to worry about processing interruptions, and the precision of our products has improved significantly," said a manager from a well - known mold manufacturing company. Another customer added, "The DC1317 has truly changed the way we do business. It has helped us save a lot of time and money, and our customers are very satisfied with the quality of our products."

If you are still struggling with large - scale mold production problems, it's time to take action. The DC1317 is your key to unlocking higher efficiency, better precision, and greater profitability. Don't let inefficiencies hold your business back. Let every minute create value with the DC1317. No more anxiety about processing interruptions. Contact us now for a consultation or to schedule a demonstration. Discover how the DC1317 can transform your large - scale mold manufacturing process today!