In the demanding world of large mold machining, precision and efficiency stand as pivotal challenges for manufacturers. The DC2025 dual-column vertical machining center emerges as a transformative solution, engineered with a robust rigidity design that drastically elevates machining stability and throughput. This article dives deep into the structural advantages and performance gains of the DC2025, empowering global procurement decision-makers to make informed, value-driven equipment investments.

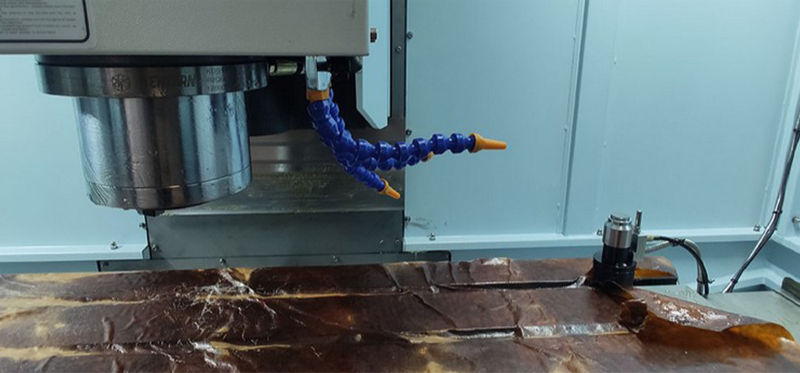

Machine tool rigidity is a decisive factor that directly influences machining accuracy and process stability. Under heavy cutting forces and high-speed operations, insufficient rigidity causes tool deflection and vibration, compromising surface finish and dimensional consistency. The DC2025’s dual-column vertical frame design innovatively counters these issues by distributing cutting loads more evenly, significantly reducing deformation during operation.

Compared to standard gantry milling machines, DC2025’s rigid dual-column vertical frame creates an optimal load path for transferring cutting forces directly into the machine’s base. This design limits frame deflections and absorption of dynamic vibrations that often degrade machining precision. The robust foundation, complemented by precision linear guides and a highly stiff spindle headstock assembly, guarantees that critical tolerances are maintained even under aggressive machining conditions.

| Performance Metric | Standard Vertical Milling Machine | DC2025 Dual-Column Center |

|---|---|---|

| Stiffness (N/µm) | 800 | 1400 |

| Max Cutting Force (kN) | 20 | 35 |

| Vibration Amplitude (µm) | 15 | 7 |

| Spindle Runout (µm) | 12 | 5 |

Application data collected from diverse manufacturing clients demonstrates DC2025’s capability to boost cutting parameters by up to 35%, reduce average machining cycle time by 22%, and cut tooling wear rates significantly—resulting in substantial cost savings. One leading automotive mold maker reported improving part accuracy by 40% while reducing scrap rates and post-processing labor. This translated into accelerated project delivery timelines and enhanced profitability.

These results epitomize how precision rigidity directly facilitates improved surface finish, tighter tolerances, and stable high-feed machining—critical parameters in large mold production where repeatability under heavy cutting loads is non-negotiable.

For procurement professionals and production managers, evaluating equipment beyond basic specifications is vital. DC2025’s engineered rigidity directly aligns with strategic goals: maximizing output, reducing downtime, and minimizing operational costs while guaranteeing product quality. This machine offers a tangible ROI by elevating throughput without compromising precision, enabling manufacturers to respond nimbly to market demands and tightening profit margins.

Furthermore, its versatile configuration supports complex 5-axis machining tasks with RTCP function, extending its application footprint from molds to aerospace and heavy equipment parts, thus future-proofing capital expenditure.

The DC2025 dual-column vertical machining center exemplifies how advanced rigidity design translates into superior machining performance, exceptional stability, and measurable economic benefits. For industries reliant on large mold manufacturing, this cutting-edge solution offers reliability and efficiency that elevate production competitiveness and operational excellence.

Equip your production line with the DC2025 to unlock new productivity benchmarks, reduce costs, and secure your competitive edge in a demanding global market.