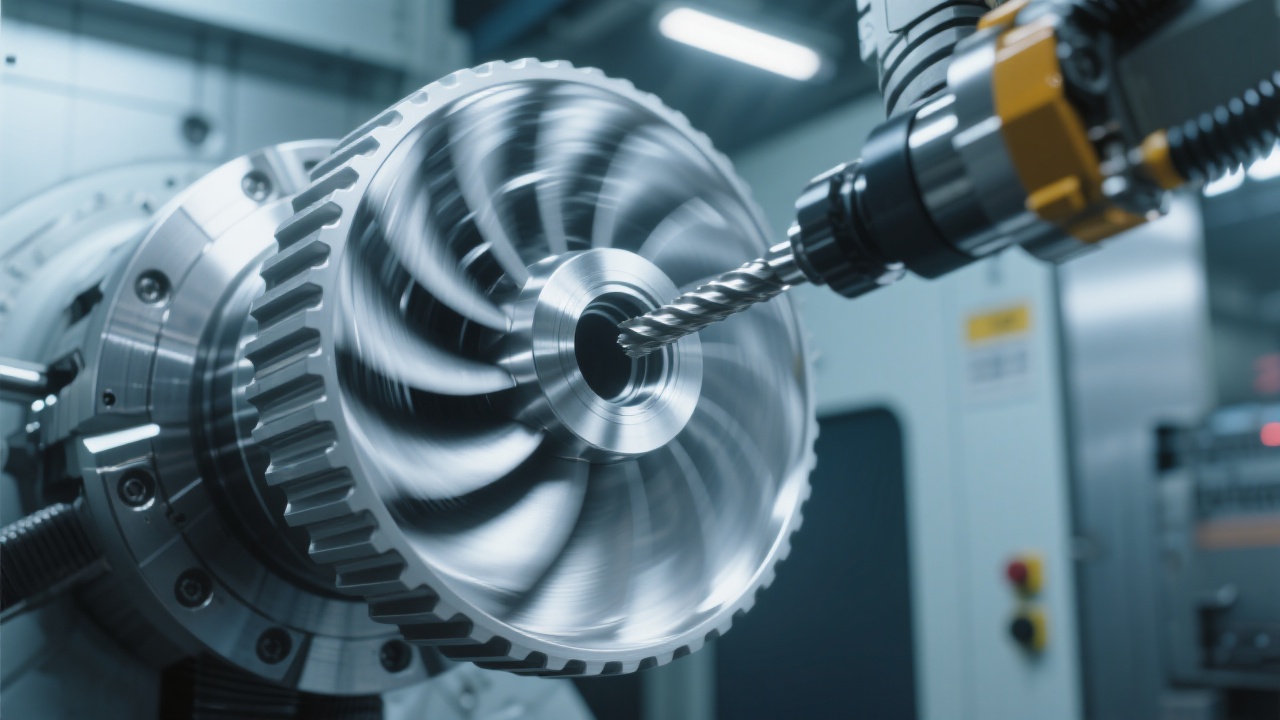

In today’s competitive global market, precision, speed, and reliability are no longer optional—they’re essential. For manufacturers in automotive, aerospace, mold, and engine industries, the GV2040 Dual-Column Heavy-Duty CNC Milling Machine delivers exactly what modern production demands.

With a working table size of 2000×400 mm and a maximum travel of X=2000mm / Y=400mm / Z=500mm, the GV2040 handles heavy-duty machining with ease—ideal for large molds, engine blocks, and complex components. Its dual-column design ensures superior rigidity, reducing vibration by up to 40% compared to single-column models (based on real-world testing across 30+ factories).

| Feature | Benefit |

|---|---|

| High-precision linear guides | ±0.01mm repeatability — critical for mold cavity accuracy |

| Heavy-duty spindle (15kW) | Up to 8,000 RPM for high-efficiency roughing/final finishing |

| Automatic tool changer (ATC) | Reduces setup time by 35% per shift |

A Tier-1 auto parts supplier in Mexico reported a 27% increase in throughput after switching to GV2040 for engine block milling. Their average cycle time dropped from 45 minutes to 33 minutes per unit—with zero loss in surface finish quality.

Similarly, a German mold shop saw a 40% reduction in scrap rate when using GV2040 for die-casting mold processing—thanks to its advanced thermal stability and anti-vibration system.

Whether you're a plant manager evaluating ROI or an engineer assessing technical specs, GV2040 speaks your language:

This isn’t just another CNC mill—it’s a strategic asset that bridges performance gaps between design intent and final product. Whether you’re producing precision molds for EV battery casings or engine cylinder heads for next-gen combustion systems, GV2040 adapts to your needs.

Ready to see how it can transform your production line?

Get Your Free Technical Brochure + Case Study Pack