Manufacturing large-size molds demands a seamless synergy between precision, rigidity, and operational stability. Companies engaged in automotive, home appliances, or aerospace industries often wrestle with the traditional CNC milling machines’ limitations—vibrations, insufficient machine rigidity, and unacceptable tolerance deviations that compromise product quality and productivity. Enter the DC1520 High-Precision CNC Milling Machine: purpose-built for oversized molds, it reinvents machining efficiency with state-of-the-art structural design and precision control.

Large mold fabrication is characterized by risks including precision variation, thermal deformation, and vibration-induced surface imperfections. Numerous workshops report precision swings exceeding 50 microns and reduced machine lifespan due to frame flexing. The absence of sufficient machine rigidity escalates wear on cutting tools, leading to frequent rework cycles and lost production time.

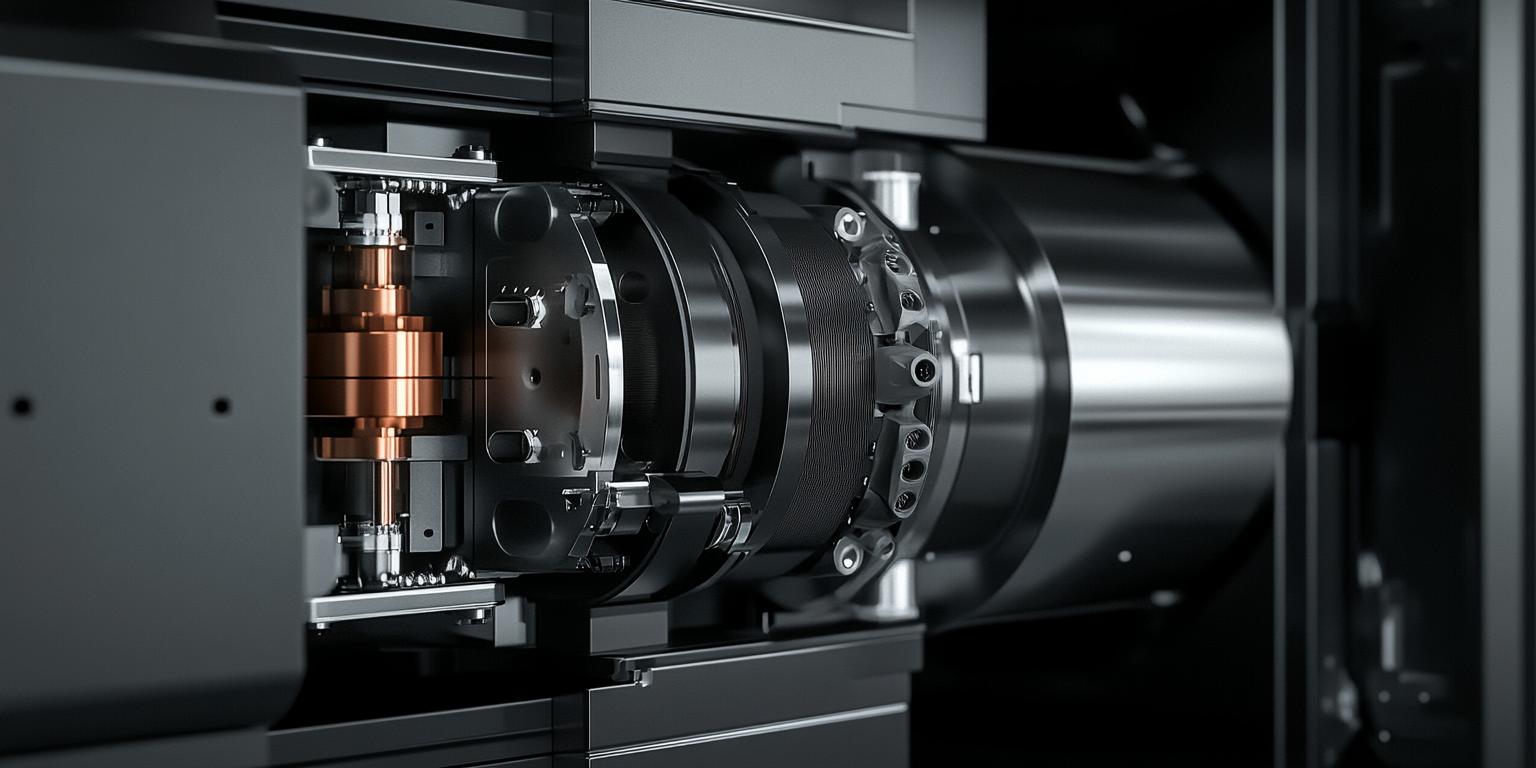

The DC1520 adopts a robust gantry structure engineered from high-grade cast iron, considerably enhancing rigidity and damping capabilities, which ensures significantly reduced vibrations during machining. Its generous three-axis travel of 1500 mm (X) × 2000 mm (Y) × 720 mm (Z) accommodates some of the largest molds in the production environment without sacrificing precision.

Complementing the axis travel is a high-precision ball screw and linear guideway system, paired with an advanced CNC controller that synchronizes multi-axis motions with minimal backlash. The high rigidity framework mitigates thermal distortion and vibration, thereby delivering consistent machining outcomes throughout extended production runs.

| Feature | DC1520 | Typical Competitors |

|---|---|---|

| X-Y-Z Travel (mm) | 1500 × 2000 × 720 | 1200 × 1600 × 600 |

| Positioning Accuracy (μm) | ±5 | ±15–20 |

| Machine Rigidity Rating | Very High (Cast Iron Gantry) | Moderate (Steel Frame) |

| Operational Lifespan (years) | 15+ years | 8–12 years |

For a leading automotive supplier, integrating the DC1520 reduced mold reject rates by 40%, due largely to improved positional repeatability and tighter tolerances. In parallel, a household appliance manufacturer significantly shortened machining cycles by 25%, thanks to the machine’s stable spindle speeds and rigid frame, reducing tool wear and unexpected stops.

These productivity gains translate to direct cost savings and a lower defect footprint, enabling clients to “make every millimeter precisely controllable” and secure market trust through consistent quality delivery.

From source-to-finish quality assurance, the DC1520 empowers mold manufacturers to escape the cycle of guesswork and costly refinements. Its optimized design underpins higher good-part yields and drastically lowers rework expenditures—key differentiators in today’s competitive manufacturing landscape.

Are you struggling with precision challenges in your large-sized mold machining?

Discover the DC1520 – Request Technical Brochure or Schedule a Live Demo