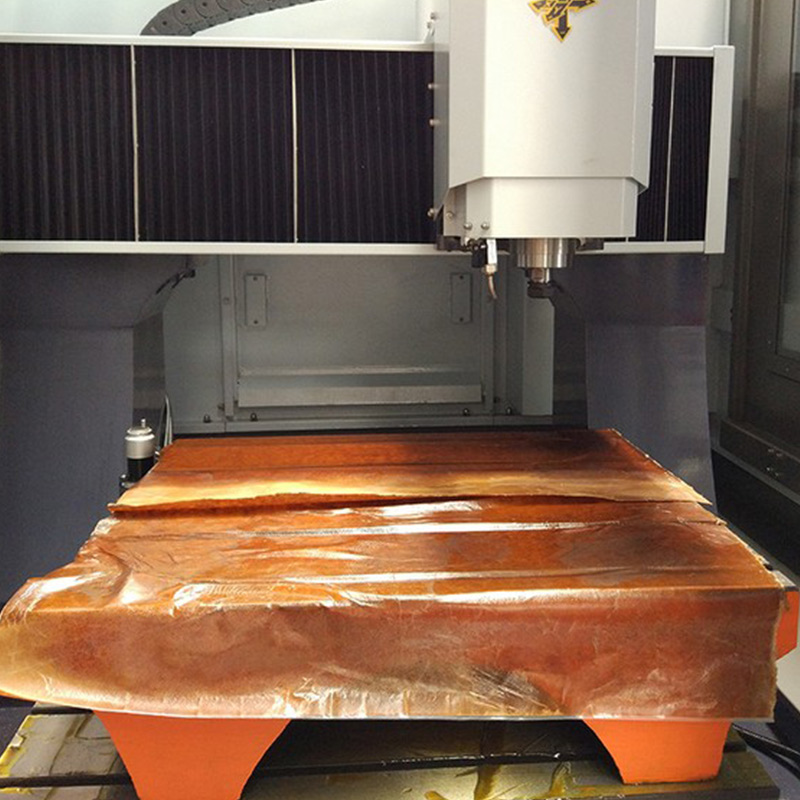

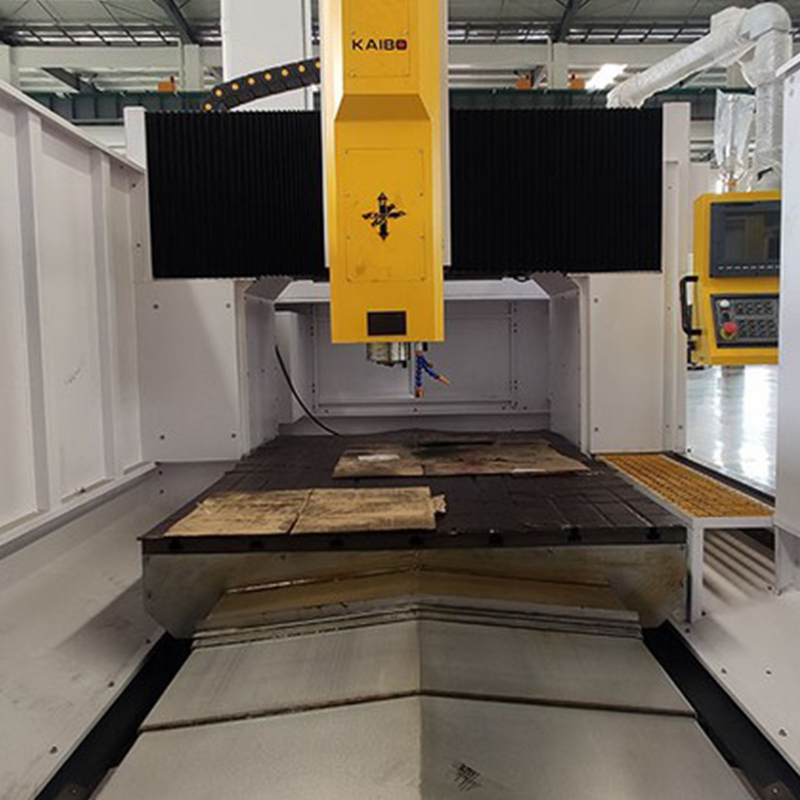

In the competitive landscape of large-scale mold manufacturing, precision and efficiency are paramount. Many manufacturers often face challenges such as low machining accuracy, poor stability, and limited processing capabilities when dealing with large and complex molds. These issues not only lead to increased production costs but also affect the quality and delivery time of products. Enter the DC1317, a large double-column CNC milling machine designed to address these pain points head - on.

The DC1317 boasts several key design features that set it apart in the market. First and foremost is its high rigidity. The machine's structure is engineered to withstand heavy loads and vibrations, ensuring stable performance during high - speed milling operations. This high - rigidity design reduces deflection and deformation, which are common causes of inaccuracies in mold machining. For example, in a typical large - scale mold machining process, the DC1317 can maintain a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm, significantly higher than many of its competitors.

Another significant feature is its smooth transmission system. The DC1317 is equipped with a high - precision ball screw and linear guide rail, which work together to provide seamless and accurate movement. This smooth transmission not only enhances the machining accuracy but also extends the service life of the machine components. With a maximum feed speed of 20m/min, the DC1317 can quickly and precisely move to the required machining positions, improving overall production efficiency.

The heavy - duty机身 of the DC1317 also plays a crucial role in its performance. The large and robust body provides a solid foundation for the machining process, reducing the impact of external forces and vibrations. Moreover, the machine has a large travel range, with an X - axis travel of 1300mm, a Y - axis travel of 1700mm, and a Z - axis travel of 800mm. This large travel range allows the DC1317 to handle large - sized molds with complex geometries, meeting the diverse needs of the mold manufacturing industry.

Let's take a look at some real - world examples to understand how the DC1317 can improve productivity and quality. A mold manufacturing company in Germany was struggling with low - quality output and long production cycles for their large - scale plastic molds. After implementing the DC1317, they witnessed a significant improvement in their operations. The machining time for a single large - scale mold was reduced by 30%, from an average of 20 hours to 14 hours. At the same time, the rejection rate of the molds decreased from 8% to 2%, thanks to the improved machining accuracy and stability of the DC1317.

When compared to other large - scale CNC milling machines in the market, the DC1317 has several unique advantages. A comparison table is presented below:

| Features | DC1317 | Competitor A | Competitor B |

|---|---|---|---|

| Positioning Accuracy | ±0.005mm | ±0.01mm | ±0.008mm |

| Repeat Positioning Accuracy | ±0.003mm | ±0.006mm | ±0.005mm |

| Maximum Feed Speed | 20m/min | 15m/min | 18m/min |

| X - axis Travel | 1300mm | 1000mm | 1200mm |

As shown in the table, the DC1317 outperforms its competitors in terms of accuracy, speed, and travel range, making it a more cost - effective and efficient choice for large - scale mold manufacturing.

We encourage you to share your thoughts and experiences in the comments section below. Do you have any questions about the DC1317 or its application in your specific mold manufacturing processes? Are you facing similar challenges as the German company we mentioned? Let's start a conversation and explore how the DC1317 can help you achieve better results.

If you're looking to enhance your mold manufacturing efficiency and quality, the DC1317 is the ideal solution. It not only improves the precision and stability of your machining processes but also helps you save time and costs, ultimately leading to higher profits. Click here to learn more about the DC1317 and take the first step towards a more productive future!