In today’s competitive mold manufacturing landscape, achieving high precision, consistent quality, and faster turnaround times for large plastic molds is no longer optional—it's essential. Traditional methods often fall short due to vibration issues, limited travel, or insufficient rigidity, leading to rework, delays, and higher costs.

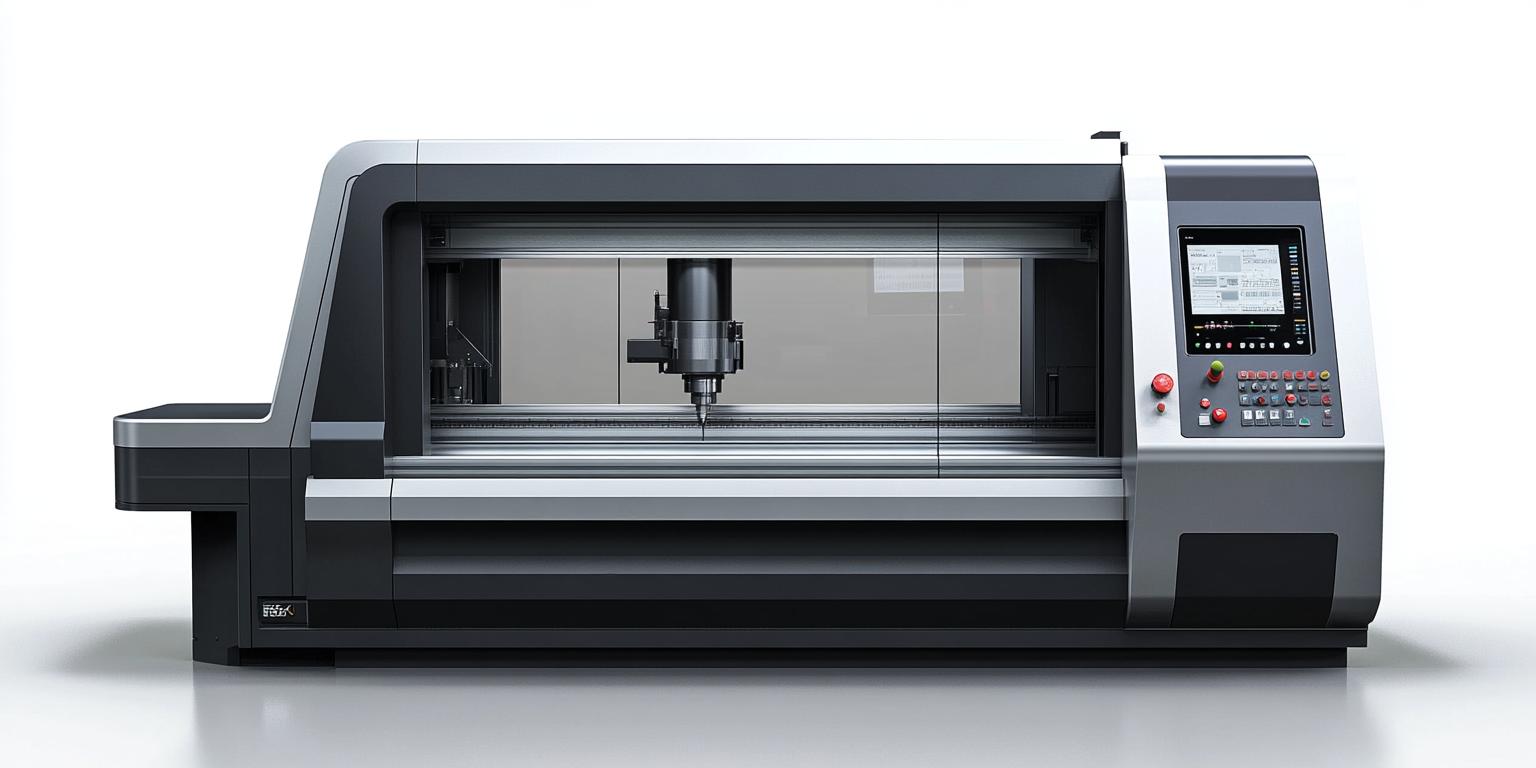

The DC1317 is not just another CNC machine—it’s a strategic investment in your mold production capability. Designed specifically for heavy-duty applications, it combines a robust cast iron frame, dual-column structure, and advanced servo drive system to deliver unmatched performance in large-scale mold machining.

| Feature | Impact on Mold Production |

|---|---|

| High Rigidity Structure | Reduces tool deflection by up to 40%, ensuring tighter tolerances (±0.02mm) |

| Large Travel Range (X/Y/Z: 1200/800/600mm) | Enables full-piece machining—no need for assembly after cutting |

| Smooth Transmission System | Minimizes chatter marks; improves surface finish (Ra ≤ 1.6 μm) |

| Heavy Cast Iron Base | Enhances stability during long cuts—ideal for complex cavity designs |

“Before switching to the DC1317, we were losing 15% of our large molds to warping and dimensional errors. Now, with one setup, we achieve 99.2% first-pass yield.”

— Zhang Wei, Senior Engineer at Shenzhen TopMold Co.

One client reported a 35% reduction in total machining time per mold—from 14 hours down to 9—with zero post-processing corrections required. This isn’t just theory—it’s measurable ROI.

Whether you're producing automotive interior components, medical device housings, or consumer electronics enclosures, the DC1317 gives you the power to produce larger, more complex molds without compromising speed or accuracy.

Don’t let outdated equipment hold back your growth. Let the DC1317 become the backbone of your mold shop—delivering precision, efficiency, and reliability every single day.

Get Your Free Technical White Paper – Learn How to Boost Mold Efficiency by 35%