In the realm of plastic mold manufacturing, precision and efficiency are the linchpins of success. However, many enterprises often grapple with a series of formidable challenges that impede their progress. Let's delve into these core pain points before exploring how the DC1317 CNC milling machine emerges as a game - changer.

One of the most prominent issues is mold deformation. During the processing, due to uneven stress distribution, the mold may deform, with a deformation rate of up to 5% in some cases. This directly affects the quality of the final product, leading to a high rejection rate, which can reach 10% - 15% in some enterprises. Moreover, precision deficiency is another headache. The required precision for plastic molds is often within ±0.05mm, but many traditional processing methods can only achieve an accuracy of ±0.1mm - ±0.2mm. This lack of precision can cause compatibility problems with other components, increasing production costs and time.

Efficiency is also a major concern. Traditional processing methods are time - consuming, with the processing time for a single large - scale plastic mold taking up to 20 - 30 hours. This slow pace not only reduces the production capacity but also makes it difficult for enterprises to meet urgent orders, resulting in potential loss of business opportunities.

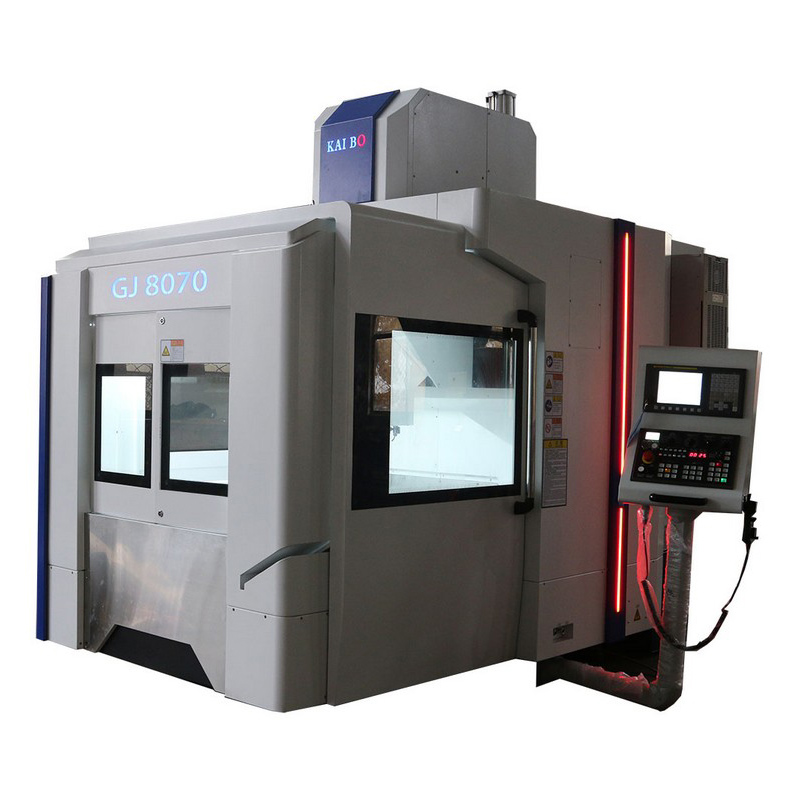

The DC1317 is equipped with a state - of - the - art transmission system that ensures smooth and stable operation. This smooth transmission can reduce vibration during processing, improving the surface finish of the mold. Tests show that it can reduce surface roughness by 30% - 40%, achieving a surface finish of Ra 0.8 - Ra 1.6μm. This directly enhances the overall quality of the mold.

With its high - rigidity structure, the DC1317 can withstand greater cutting forces. This is crucial for processing hard - to - machine materials. It can maintain the stability of the processing process, reducing the probability of mold deformation. In practical applications, it can control the deformation rate within ±0.01mm, significantly improving the precision of the mold.

The heavy - duty body of the DC1317 provides a solid foundation for the machine. It can effectively absorb the impact and vibration generated during processing, ensuring the long - term stability of the equipment. This stability is essential for continuous and high - precision processing, which can increase the service life of the machine by 20% - 30%.

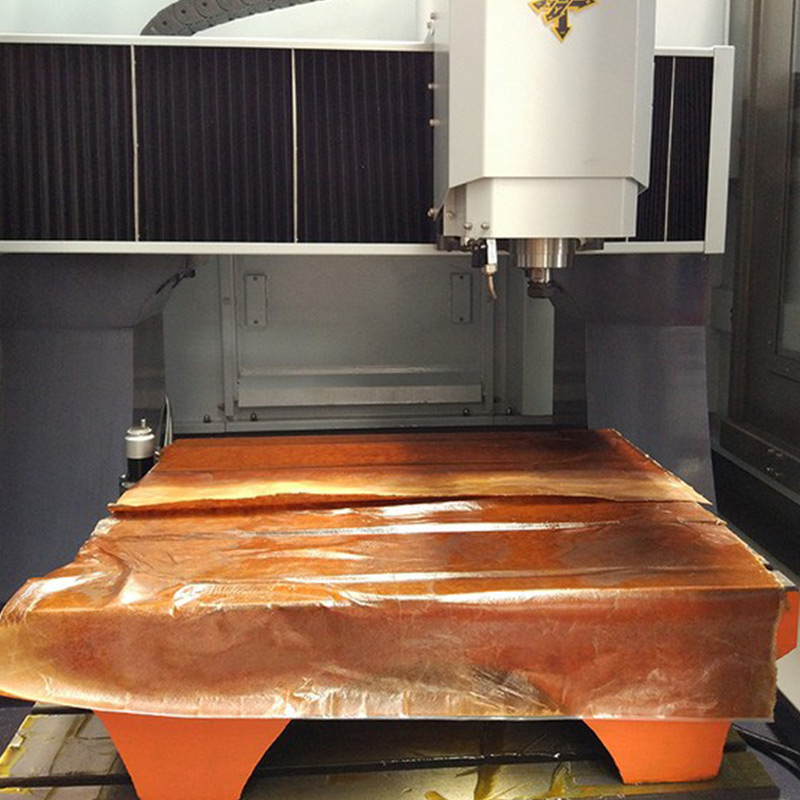

The extra - large stroke of the DC1317 allows it to handle larger - sized molds. It can process molds with a maximum size of 1300mm×1700mm, which is much larger than many similar models in the market. This greatly expands the application range of the machine, meeting the diverse needs of different customers.

Let's take a look at some real - world customer cases. A mold manufacturing company in Germany was struggling with low - efficiency and low - precision processing of complex plastic molds. After adopting the DC1317, they witnessed a significant improvement. The processing time for a single mold was reduced from 25 hours to 15 hours, a 40% reduction. The precision of the mold was improved to ±0.01mm, and the rejection rate dropped from 12% to 3%. The customer commented, "The DC1317 is not just a piece of equipment; it is our reliable partner in mold processing. It has helped us save a lot of time and cost, and improved our market competitiveness."

When compared with similar models in the market, the DC1317 stands out in terms of applicability, stability, and cost - effectiveness. Many similar models have limited processing sizes and cannot meet the needs of large - scale molds. In terms of stability, the DC1317's high - rigidity structure and heavy - duty body ensure long - term stable operation, while some similar models may experience frequent breakdowns. In terms of cost - effectiveness, the DC1317 can achieve high - precision processing at a relatively low cost, providing more value for money.

Now, we invite you to share your experiences. What kind of mold processing challenges do you encounter most frequently? Whether it's deformation, precision issues, or efficiency problems, we are here to help. The DC1317 is not just a piece of equipment; it is your partner in mold processing, making every process more stable, faster, and more accurate. If you want to learn more about how the DC1317 can solve your specific problems, click here to get in touch with our experts and get personalized solutions.