Large-scale mold machining often presents numerous challenges for manufacturers. One of the most prominent issues is deformation errors. Due to the large size and complex structure of these molds, traditional machining equipment may struggle to maintain the required precision, leading to deformation during the machining process. This not only affects the quality of the final product but also increases the scrap rate, resulting in significant financial losses for enterprises. Additionally, low efficiency is another major pain point. Traditional equipment usually has limited processing capabilities, long processing cycles, and low production efficiency, which cannot meet the market's demand for rapid delivery.

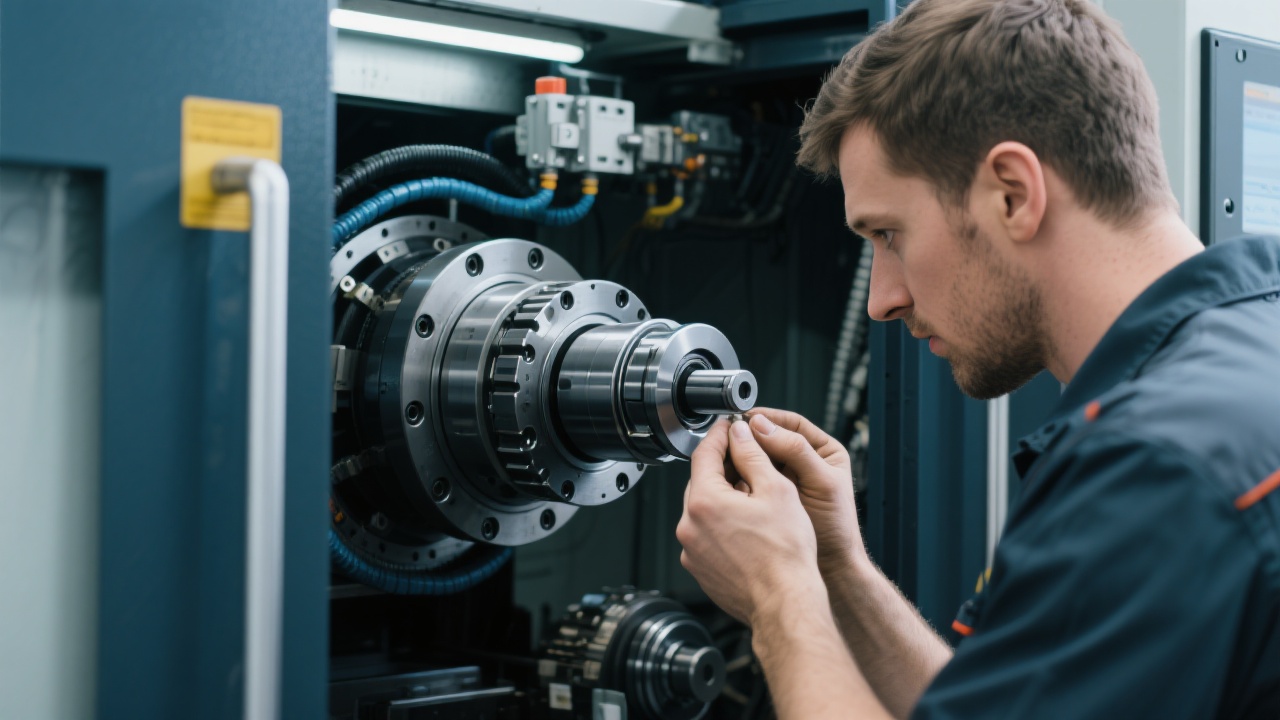

The DC1520 high-precision CNC milling machine is specifically designed for large-scale mold machining, featuring a gantry structure. This structure provides excellent stability during the machining process, effectively reducing vibration and ensuring the accuracy of the machining. Compared with traditional structures, the gantry structure can better withstand the forces generated during high-speed machining, thereby improving the overall stability of the equipment.

With an ultra-large three-axis travel of 1500×2000×720mm, the DC1520 can cover a wide range of machining areas. This means that it can handle large-scale molds without the need for multiple setups, greatly improving processing efficiency. Whether it's a large automotive mold or an industrial equipment mold, the DC1520 can easily handle it.

The DC1520 boasts excellent high-precision positioning ability, with a repeat positioning accuracy of ±0.005mm. This high-precision positioning ensures that each machining operation is carried out with high accuracy, effectively reducing errors and improving the quality of the final product. In the industry, this level of precision is highly competitive, allowing enterprises to produce high-quality molds that meet strict market requirements.

When compared with similar products on the market, the DC1520 stands out in terms of rigidity, repeat positioning accuracy, and processing consistency. In a recent industry comparison test, the DC1520 demonstrated significantly higher rigidity, which means it can better withstand the forces during machining and maintain its structural integrity. In terms of repeat positioning accuracy, as mentioned earlier, its ±0.005mm accuracy far exceeds that of many similar products. Moreover, in terms of processing consistency, the DC1520 can ensure that each mold produced has the same high quality, reducing the variability between products.

| Product | Rigidity | Repeat Positioning Accuracy | Processing Consistency |

|---|---|---|---|

| DC1520 | High | ±0.005mm | High |

| Similar Product A | Medium | ±0.01mm | Medium |

| Similar Product B | Low | ±0.02mm | Low |

Many enterprises have already benefited from using the DC1520. For example, a mold factory in the automotive industry used the DC1520 for large-scale mold machining. After using the equipment, the factory's product yield increased from 80% to 95%, significantly reducing the scrap rate. At the same time, the processing cycle was shortened by 30%, allowing the factory to meet customer delivery requirements more quickly. This not only improved the factory's market competitiveness but also increased its profitability.

The DC1520 high-precision CNC milling machine offers significant value to enterprises. Firstly, it greatly improves production efficiency. With its large three-axis travel and high-precision positioning ability, it can complete large-scale mold machining in a shorter time, reducing production cycles and increasing output. Secondly, it ensures product quality. The high rigidity and excellent processing consistency of the DC1520 ensure that each mold produced meets high-quality standards, reducing the number of defective products. Finally, it enhances the competitiveness of enterprises. By providing high-quality products and fast delivery, enterprises can gain a larger market share and improve their brand image.

If you are looking for a solution to improve the precision and efficiency of large-scale mold machining, the DC1520 is your ideal choice. It's not just a piece of equipment; it's your production partner that can help you win in the market. Don't miss this opportunity to transform your mold machining process.

Click here to learn more about DC1520 and get a customized solution!