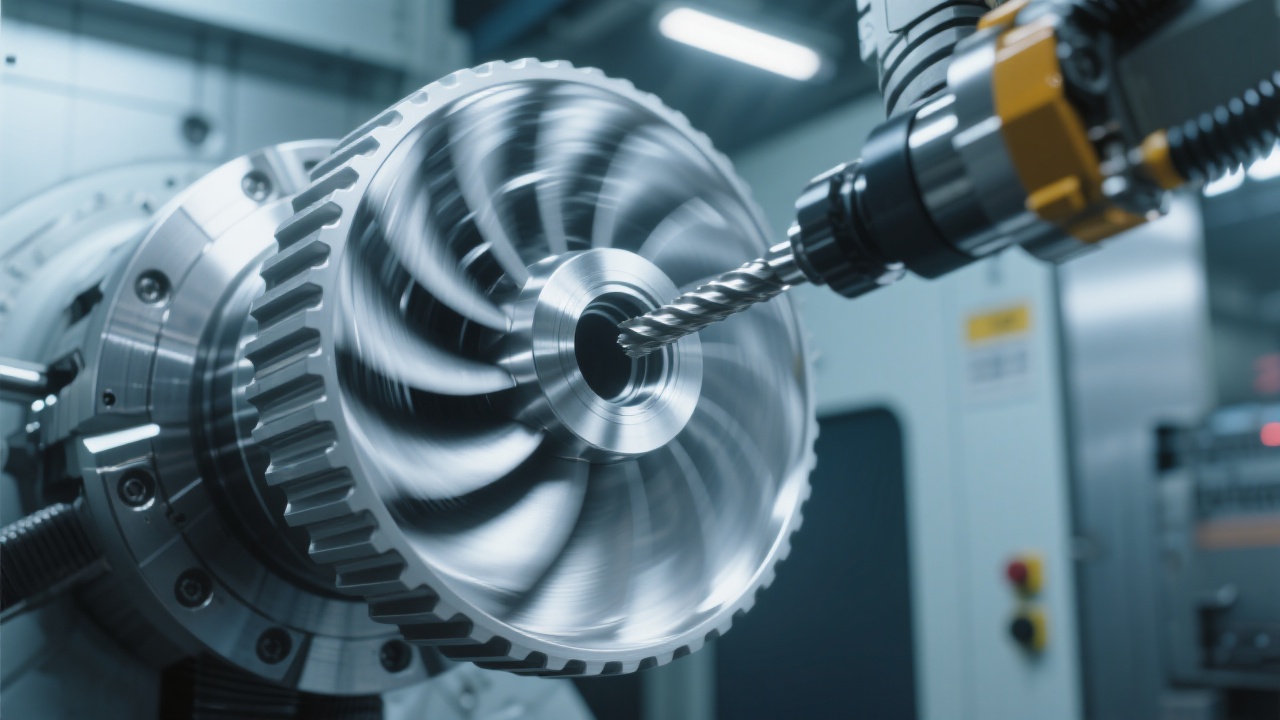

In the realm of heavy - duty machining, precision and efficiency are the cornerstones of success. The FANUC GV2030 heavy - duty machining center, equipped with the Fanuc controller, has emerged as a game - changer. This article will delve deep into the high - precision positioning technology of the Fanuc controller and its application value in heavy - duty machining centers.

The FANUC GV2030 heavy - duty machining center finds its applications in a wide range of industries, such as aerospace, automotive, and energy. These industries demand high - precision and high - efficiency machining, and the FANUC GV2030 rises to the challenge. Its ability to handle large - scale and complex workpieces makes it an ideal choice for enterprises aiming for high - end production.

The Fanuc controller is the heart of the FANUC GV2030 heavy - duty machining center. One of its most prominent features is its high - precision positioning technology. The positioning accuracy of the Fanuc controller can reach up to ±0.005mm. This high level of accuracy ensures that the machining center can produce parts with extremely tight tolerances. In addition, the controller has excellent long - term stability. It can maintain its performance even after continuous operation for over 20,000 hours, which is far superior to many of its competitors.

| Technical Indicator | Value |

|---|---|

| Positioning Accuracy | ±0.005mm |

| Long - term Stability (Continuous Operation) | Over 20,000 hours |

When compared with other controllers in the market, the Fanuc controller shows significant advantages in terms of precision control and machining efficiency. In a performance test, a machining center equipped with the Fanuc controller completed a complex machining task in 30% less time than a similar machine with a competitor's controller. Moreover, the parts produced by the Fanuc - controlled machining center had a scrap rate that was 50% lower, indicating a much higher level of quality control.

To better understand the application value of the Fanuc controller, let's consider a simulation scenario. In a heavy - duty machining process for aerospace components, the Fanuc controller can accurately position the cutting tool, reducing the need for multiple set - ups and re - adjustments. This not only saves time but also reduces the risk of human error. As a result, the overall production cycle is shortened, and the quality of the final product is improved.

For enterprises, the FANUC GV2030 heavy - duty machining center with the Fanuc controller brings a significant boost to production competitiveness. The high - precision positioning technology and excellent stability can improve the production efficiency by up to 40%. This means that enterprises can produce more parts in less time, reducing production costs. At the same time, the high - quality products produced can help enterprises gain a larger market share and enhance their brand image.

In conclusion, the Fanuc controller's high - precision positioning technology is a revolutionary force in the heavy - duty machining industry. The FANUC GV2030 heavy - duty machining center equipped with this controller can significantly improve production efficiency and product quality, bringing enterprises a strong competitive edge in the market. If you want to take your heavy - duty machining business to the next level, click here to learn more about the FANUC GV2030 and the Fanuc controller.