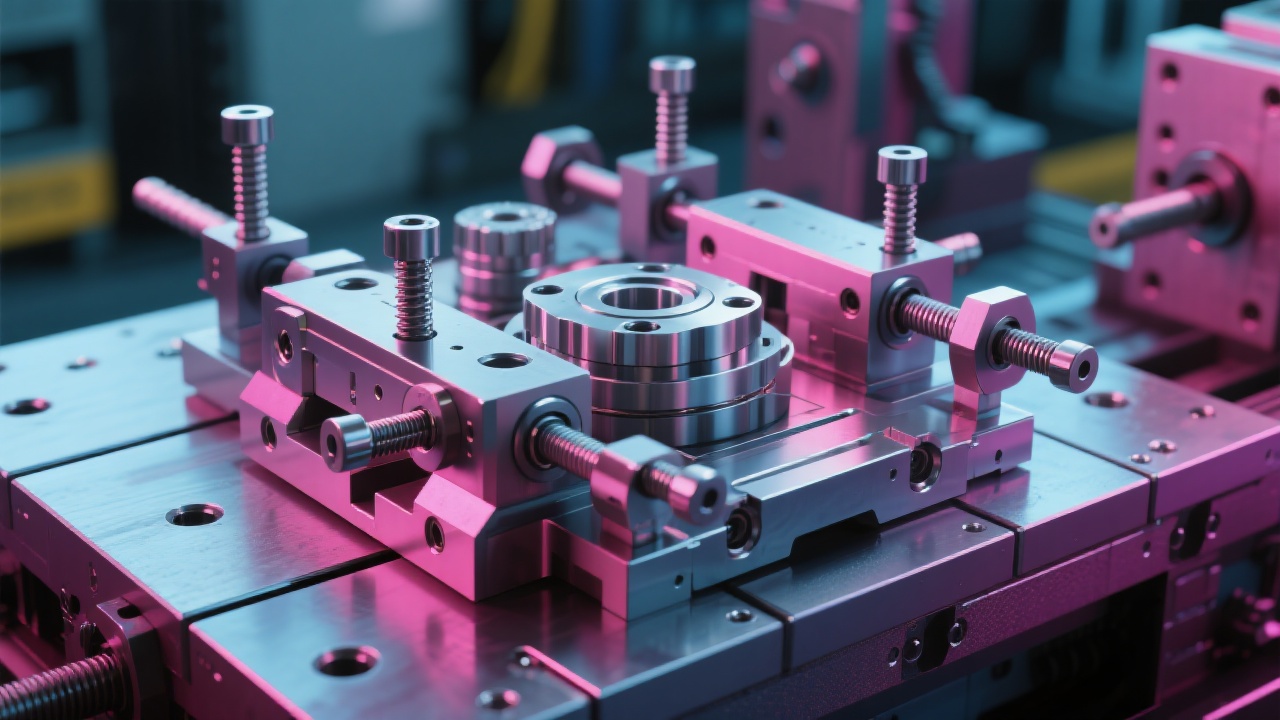

In the competitive field of large-scale mold manufacturing, achieving high precision while maintaining elevated machining efficiency remains a crucial challenge. The introduction of the DC1520 high-precision CNC gantry milling machine offers a transformative solution to these challenges. Featuring optimized three-axis travel design and robust structural rigidity, the DC1520 significantly improves machining accuracy, enhances processing speeds, and drives cost-effective production.

The DC1520 is engineered specifically for large-scale mold processing, boasting an extensive three-axis travel span of 1500 mm (X-axis), 2000 mm (Y-axis), and 800 mm (Z-axis). This dimensioning accommodates a broad variety of complex mold sizes without compromising workspace efficiency. The machine’s bridge-type gantry frame is fabricated from high-strength cast iron, subject to precision annealing treatment to fully relieve internal stresses. This ensures exceptional rigidity and thermal stability during prolonged operation.

A critical factor contributing to the DC1520’s precision is its high-accuracy linear guide rails combined with preloaded ball screws. These components collectively deliver repeatability within ±0.005 mm and positional accuracy up to ±0.01 mm. Moreover, a closed-loop servo control system ensures consistent feed rates and stable cutting forces, which optimizes surface finish quality and reduces tool wear.

The integration of the DC1520 in production lines has demonstrably accelerated machining throughput. An industrial case study involving a mold manufacturer reported a 30% reduction in machining cycle times after upgrading to the DC1520, attributable to its rapid acceleration and deceleration capabilities (up to 1.2 m/s²) and stable high spindle speeds reaching 12,000 rpm. The machine’s high rigidity minimizes vibration during heavy cutting, translating into surface finishes exceeding Ra0.4 µm according to ISO standards.

| Performance Metric | Before DC1520 | After DC1520 Integration |

|---|---|---|

| Machining Cycle Time | 10 hours | 7 hours |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm |

| Dimensional Accuracy | ±0.02 mm | ±0.01 mm |

| Tool Life | 200 hours | 320 hours |

A medium-sized mold production enterprise specializing in automotive components reported that the DC1520 enabled the machining of complex molds with dimensions up to 2000 mm × 1500 mm with consistently tight tolerances. The machine’s ability to maintain positional accuracy during multi-hour continuous operations significantly reduced rework rates from 8% down to 2%, directly impacting profitability.

Furthermore, the enterprise benefited from enhanced flexibility in coping with customized orders due to the DC1520’s easy-to-program CNC interface and modular tooling options. Together, these improvements increased their order fulfillment rate by over 25%, strengthening their competitive position in both domestic and international markets.

The DC1520 stands out as a reliable solution for high-precision, large-scale mold manufacturing due to its harmonization of robust structural design, advanced motion accuracy, and flexible operational parameters. Enterprises aiming to reduce production costs, improve surface and dimensional quality, and shorten lead times will find this platform a strategic asset.

Ideal sectors for deployment include automotive mold fabrication, aerospace component tooling, and industrial machinery parts manufacturing. Its versatility ensures consistent performance for diverse product requirements, while technological innovations embedded in the DC1520 promise future scalability.

Discover how the DC1520 gantry milling machine can revolutionize your large-scale mold production by delivering unmatched precision and efficiency. Explore the DC1520 Solutions Now