In the field of machining complex large - scale parts, manufacturers often encounter a series of challenges, especially when it comes to processing large fuselage components, lay - up molds, and composite structures. The main pain points revolve around low processing efficiency and insufficient precision. For instance, in the aerospace industry, the machining accuracy of large fuselage components directly affects the safety and performance of the aircraft. An error of just 0.1mm can lead to significant quality issues, and the long processing cycle also increases production costs.

The GV1625 double - column large - scale CNC milling machine is specifically designed to address these challenges. Its design concept is centered around creating a stable and high - precision machining platform. The key to its success lies in its rigid steel structure. This structure provides excellent stability during the cutting process, effectively reducing vibrations and deflections that can affect machining accuracy.

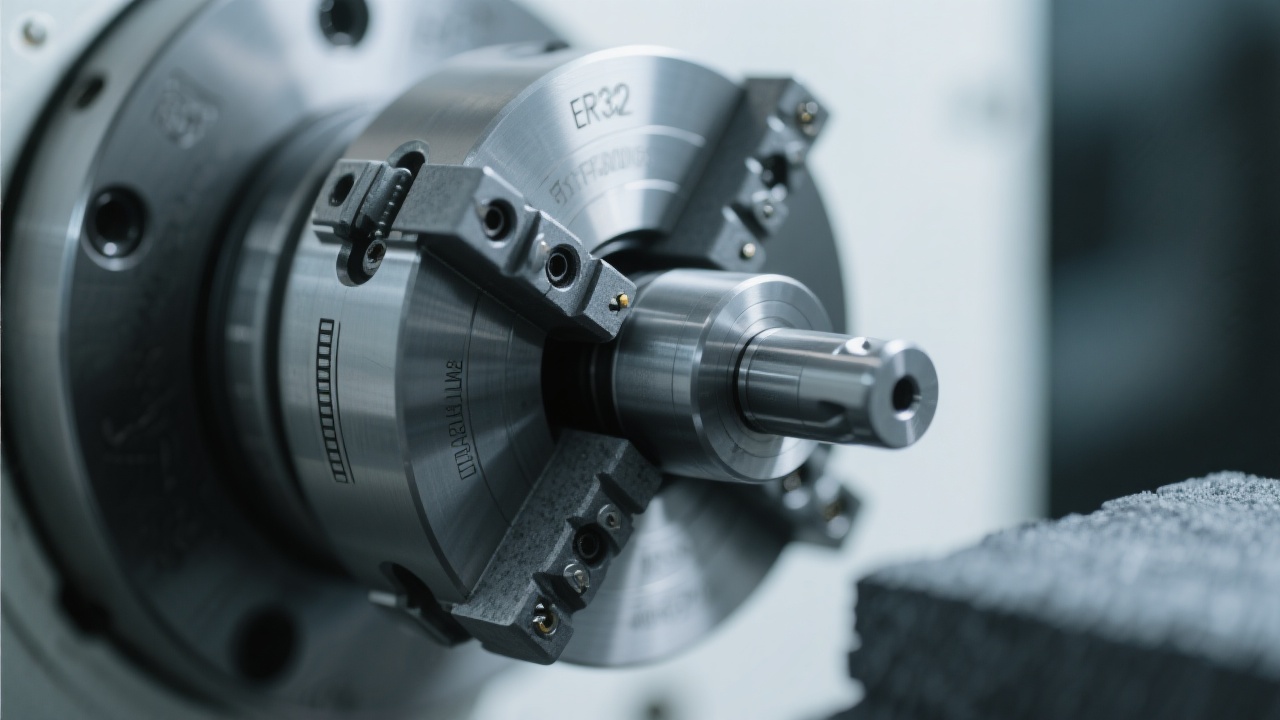

The GV1625 is equipped with advanced control systems and high - performance spindles. The control system can accurately control the movement of the tool, ensuring high - precision machining. The spindle can reach a maximum speed of 8000 rpm, enabling efficient material removal. In addition, the machine has a large working range, with a table size of 1600mm×2500mm, which can easily accommodate large workpieces.

Fuselage Components: When machining large fuselage components, the GV1625's rigid structure ensures stable cutting, which is crucial for achieving high - precision machining of thin - walled parts. It can effectively reduce the deformation of the workpiece during processing, improving the overall quality of the fuselage components.

Lay - up Molds: For lay - up molds, the GV1625 can accurately machine complex surface contours. Its high - speed spindle and precise control system can ensure the smoothness and accuracy of the mold surface, which is essential for the quality of composite material lay - up.

Composite Structures: When processing composite structures, the GV1625 can handle different types of composite materials. Its stable cutting performance can prevent delamination and fiber pull - out, improving the processing quality of composite structures.

Customers in the consideration stage are mainly concerned about the performance and applicability of the processing equipment. The GV1625 meets these concerns in several aspects. In terms of performance, its high - precision machining and high - efficiency processing capabilities can significantly improve production efficiency and product quality. In terms of applicability, its large working range and ability to handle different materials make it suitable for a variety of complex large - scale part processing scenarios.

A well - known aerospace company was facing challenges in machining large fuselage components. The previous equipment had low processing efficiency and could not meet the required precision. After using the GV1625, the processing efficiency increased by 30%, and the machining precision improved from ±0.2mm to ±0.05mm. The customer was highly satisfied with the performance of the GV1625 and provided positive feedback, stating that it had solved their long - standing processing problems.

If you are also struggling with the processing of complex large - scale parts, don't miss the GV1625. Click here to learn more about the product details and book a consultation now!