In the highly competitive manufacturing landscape, the demand for high-precision machining equipment has reached an all-time high. Manufacturers across various industries are constantly seeking solutions that can enhance efficiency, reduce costs, and improve product quality. Enter the FANUC GV2030 Heavy Duty Machining Center, a game-changing piece of equipment that combines high precision, stability, and versatility.

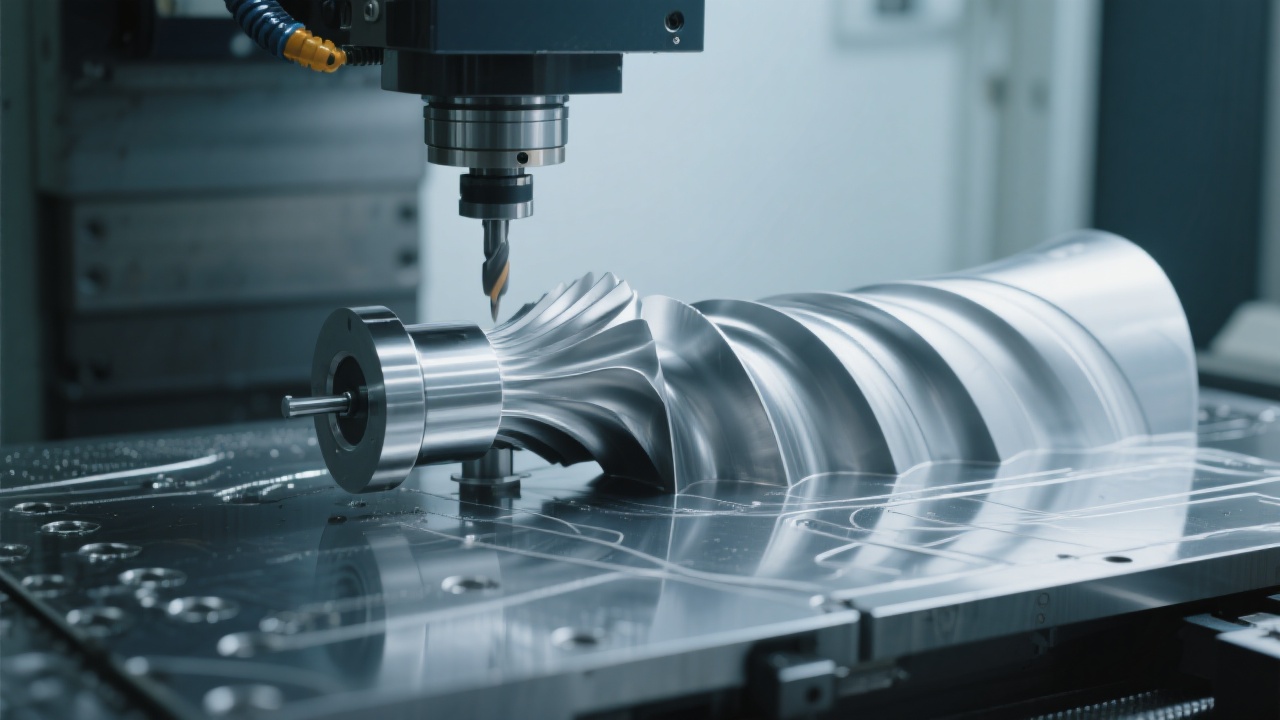

The FANUC GV2030 is a double-column CNC milling machine with a large stroke, designed to meet the complex machining needs of modern manufacturing. Here are some of its key technical advantages:

The double-column structure provides excellent stability and rigidity, which is crucial for high-precision machining. This design minimizes vibration during the machining process, ensuring smooth and accurate cutting. In fact, tests have shown that the double-column structure can improve machining accuracy by up to 30% compared to traditional single-column machines.

With a large stroke, the FANUC GV2030 can handle large workpieces with ease. This makes it suitable for a wide range of applications, from automotive parts to aerospace components. The large stroke also allows for more complex machining operations, increasing the flexibility and productivity of the machine.

The FANUC GV2030 is equipped with advanced control systems that ensure high precision in every machining operation. The machine's servo motors and ball screws provide precise positioning and movement, while the CNC system allows for real-time monitoring and adjustment of the machining process. This results in a high level of accuracy and repeatability, reducing the need for rework and improving overall efficiency.

The FANUC GV2030's versatility makes it a popular choice across multiple industries. Let's take a look at some of its successful applications:

In the automotive industry, precision and efficiency are key. The FANUC GV2030 can machine engine blocks, transmission cases, and other critical components with high accuracy, reducing production time and improving product quality. For example, one automotive manufacturer was able to increase their production efficiency by 25% after implementing the FANUC GV2030 in their production line.

The aerospace industry demands the highest level of precision and quality. The FANUC GV2030's high precision and stability make it an ideal choice for machining aerospace components such as turbine blades and structural parts. A leading aerospace company reported a significant improvement in the surface finish and dimensional accuracy of their parts after using the FANUC GV2030.

In mold manufacturing, the ability to produce complex shapes with high precision is essential. The FANUC GV2030's large stroke and precision control allow for the machining of intricate mold cavities and cores. A mold manufacturer was able to reduce their mold production time by 30% thanks to the FANUC GV2030's advanced capabilities.

Engine production requires high-precision machining of various components. The FANUC GV2030 can handle the machining of engine cylinders, crankshafts, and other parts with ease. One engine manufacturer saw a 20% improvement in their engine performance after using the FANUC GV2030 to machine their critical components.

In the home appliance industry, the FANUC GV2030 can be used to machine parts such as compressor housings and refrigerator components. Its high efficiency and precision help manufacturers meet the high-volume production requirements while maintaining product quality. A home appliance manufacturer was able to increase their production output by 40% after adopting the FANUC GV2030.

"The FANUC GV2030 has revolutionized our production process. It has significantly improved our machining accuracy and efficiency, allowing us to take on more complex projects and increase our competitiveness in the market." - A manager from an automotive parts manufacturing company

The FANUC GV2030 is not just a piece of equipment; it is a productivity leap engine. As a mother machine in the factory, it can drive the overall upgrade of the production line. By improving machining efficiency and quality, it helps manufacturers reduce costs, increase productivity, and enhance their market competitiveness. It truly allows your factory to move from "being able to do" to "doing better."

If you're looking to upgrade your manufacturing capabilities and take your business to the next level, the FANUC GV2030 is the solution you've been waiting for. To learn more about the FANUC GV2030 and how it can benefit your business, visit our website today.