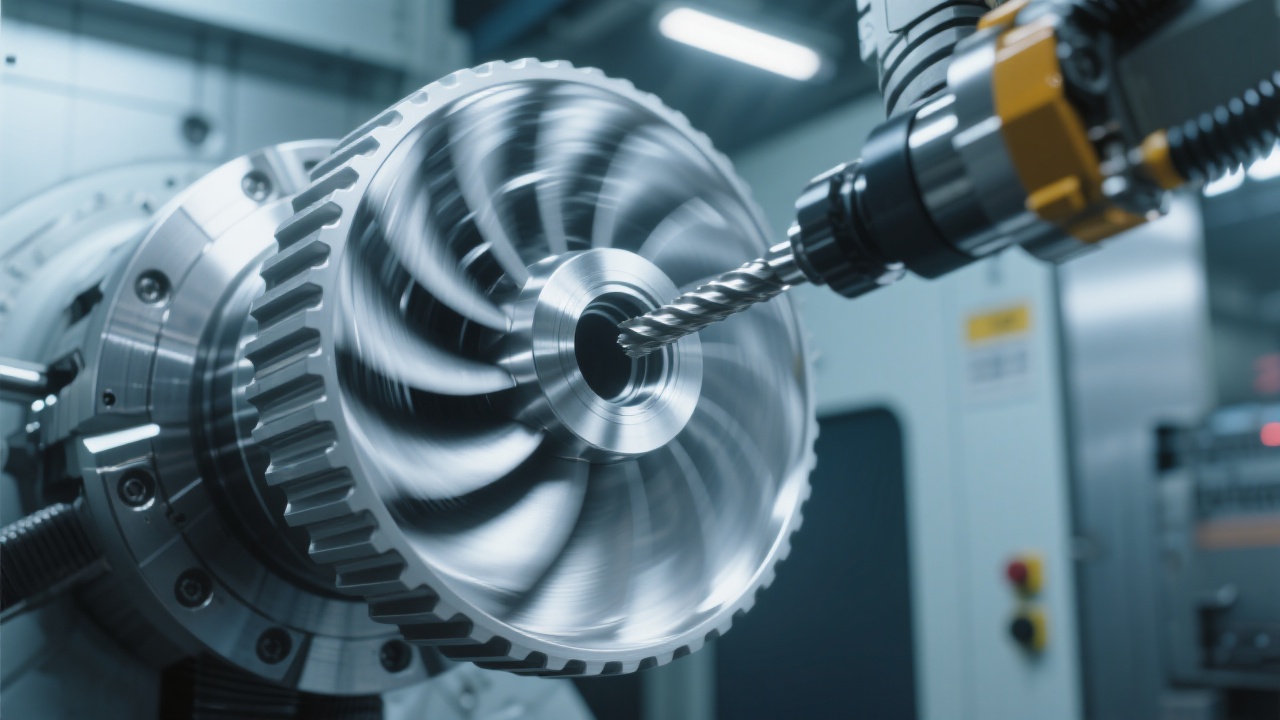

In the highly competitive home appliance manufacturing industry, the processing of heavy parts demands high - precision and efficient equipment. The GV2040 heavy - duty CNC milling machine with a large worktable emerges as a game - changer. This article delves into the process optimization and practical application of the GV2040 in the home appliance industry's heavy - part processing.

The GV2040 is a double - column large - stroke CNC milling machine. Its unique double - column structure provides excellent stability. With a worktable load capacity of up to 5 tons, it can easily handle large and heavy home appliance parts. The maximum travel of the X, Y, and Z axes reaches 2000mm, 4000mm, and 800mm respectively, enabling it to process parts of various sizes.

In terms of precision, the GV2040 is equipped with high - precision ball screws and linear guides, which can achieve a positioning accuracy of ±0.02mm and a repeat positioning accuracy of ±0.01mm. This high - precision performance ensures the quality of home appliance parts, especially for complex parts with high - precision requirements.

One of the key points of using the GV2040 in the home appliance industry is to optimize the processing procedures. By adjusting the cutting parameters such as cutting speed, feed rate, and cutting depth, the processing efficiency can be significantly improved. For example, in the processing of a large - sized refrigerator compressor housing, through optimized cutting parameters, the processing time can be reduced by 30% compared with the traditional process.

In addition, the use of advanced CAM software for tool path planning can also improve the processing quality. The CAM software can generate the most reasonable tool path according to the shape and structure of the part, reducing unnecessary tool movements and improving the utilization rate of the tool.

Let's take a well - known home appliance manufacturing enterprise as an example. Before using the GV2040, the enterprise faced problems such as low processing efficiency and unstable quality in the production of heavy parts. After introducing the GV2040 and optimizing the processing procedures, the production efficiency of heavy parts increased by 40%, and the defective rate decreased from 5% to 1%.

The operation of the GV2040 is relatively user - friendly. First, the operator needs to perform a pre - operation inspection, including checking the lubrication system, hydraulic system, and electrical system. Then, load the workpiece onto the worktable and use the fixture to fix it firmly.

Next, input the processing program into the CNC system. The CNC system will automatically control the movement of the machine tool according to the program. During the processing, the operator should monitor the processing status in real - time and deal with any abnormal situations promptly.

To ensure the long - term stable operation of the GV2040, regular maintenance is essential. The machine tool should be cleaned regularly, and the lubricating oil and hydraulic oil should be replaced on time. In addition, the operator should be trained to operate the machine tool correctly to avoid human - induced faults.

With the development of the home appliance industry towards high - end and intelligent, the requirements for heavy - part processing are also getting higher and higher. The GV2040 will continue to upgrade and improve, such as integrating intelligent control systems and remote monitoring functions, to better meet the needs of the industry.

Are you ready to enhance your home appliance manufacturing efficiency and quality? Click here to learn more about the GV2040 CNC milling machine and take the first step towards production upgrade!