In the field of large mold processing, enterprises often encounter several critical challenges. Firstly, precision is a major concern. In high - end mold manufacturing, a deviation of even 0.01mm can lead to product defects. For example, in the automotive industry, molds for engine parts require extremely high precision. A study shows that approximately 30% of defective large molds are due to insufficient precision in the processing stage.

Secondly, the lack of rigidity in processing equipment is another significant issue. When processing large and complex molds, the machine tool needs to withstand high - intensity cutting forces. If the equipment has poor rigidity, it may cause vibration during processing, resulting in rough surfaces and inaccurate dimensions of the mold. Statistics indicate that about 25% of mold processing rework is related to the problem of insufficient rigidity.

Finally, low efficiency is also a headache for manufacturers. Long processing cycles not only increase production costs but also delay delivery times. In some cases, the processing time for a single large mold can be extended by up to 50% due to inefficient equipment.

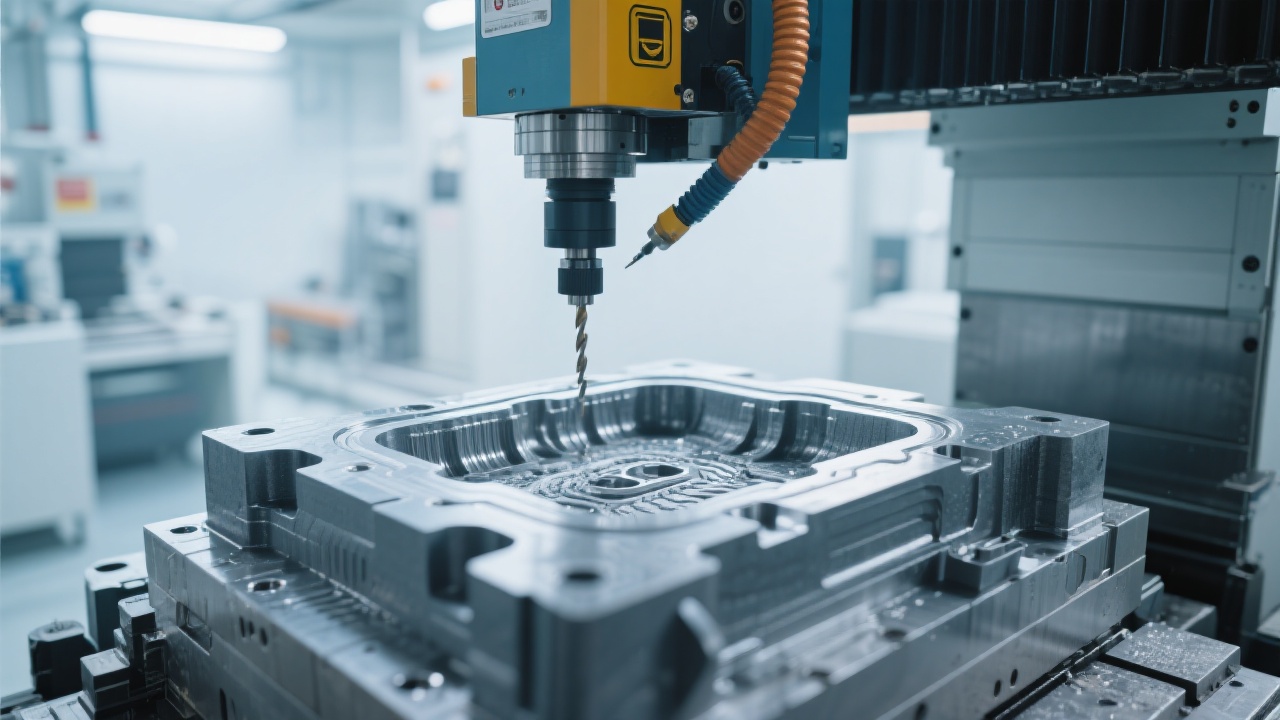

To address these pain points in large mold processing, DC2025 gantry CNC milling machine has emerged as a professional solution. Developed with advanced technology and years of industry experience, DC2025 is specifically designed to meet the complex requirements of large mold processing.

DC2025 excels in both precision and rigidity. In terms of precision, it is equipped with high - precision ball screws and linear guides, which can achieve a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm. This high - precision configuration ensures that the machine tool can accurately process molds with complex shapes and strict dimensional requirements.

Regarding rigidity, DC2025 features a robust gantry structure made of high - strength cast iron. The thick - walled castings and optimized internal rib design enhance the overall rigidity of the machine tool. It can easily withstand high - intensity cutting forces without significant vibration, ensuring stable and high - quality processing.

Let's take a look at a real - world case. A well - known mold manufacturing company in Germany was facing challenges in processing large aviation molds. The original equipment had low precision and poor rigidity, resulting in a high rejection rate of up to 15%. After replacing with DC2025 gantry CNC milling machine, the rejection rate dropped to less than 2% within three months. Moreover, the processing efficiency increased by 40%, significantly reducing production costs and improving delivery times.

When compared with similar products in the market, DC2025 shows obvious professional advantages. In a comparative test of several well - known gantry CNC milling machines, DC2025 outperformed its competitors in terms of precision, rigidity, and processing efficiency. The positioning accuracy of some competing products is only ±0.01mm, while DC2025 can reach ±0.005mm. In terms of rigidity, the vibration amplitude of DC2025 during high - speed cutting is 30% lower than that of some similar products.

| Product | Positioning Accuracy | Rigidity (Vibration Amplitude) | Processing Efficiency |

|---|---|---|---|

| DC2025 | ±0.005mm | Low | High |

| Competitor A | ±0.01mm | Medium | Medium |

| Competitor B | ±0.012mm | High | Low |

By choosing DC2025, enterprises can significantly improve the quality of their large molds, reduce rework and scrap rates, and ultimately enhance their market competitiveness. The high - precision and high - efficiency processing capabilities of DC2025 can also help enterprises save production costs and increase profits. In the long run, it is a wise investment for mold manufacturers aiming for high - end and large - scale production.

If you are still struggling with the challenges of large mold processing, don't miss the opportunity to experience the professional, precise, and efficient performance of DC2025. Click here to learn more about DC2025 and transform your mold processing business!