Unlocking Precision and Efficiency in Mold Manufacturing: How the DC1317 CNC Milling Machine Leads the Way

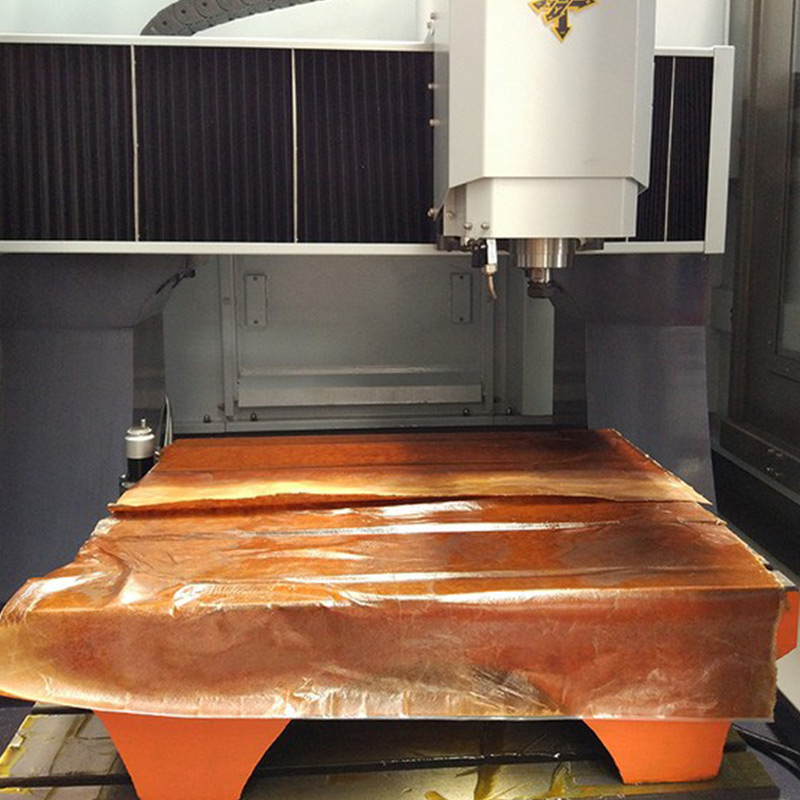

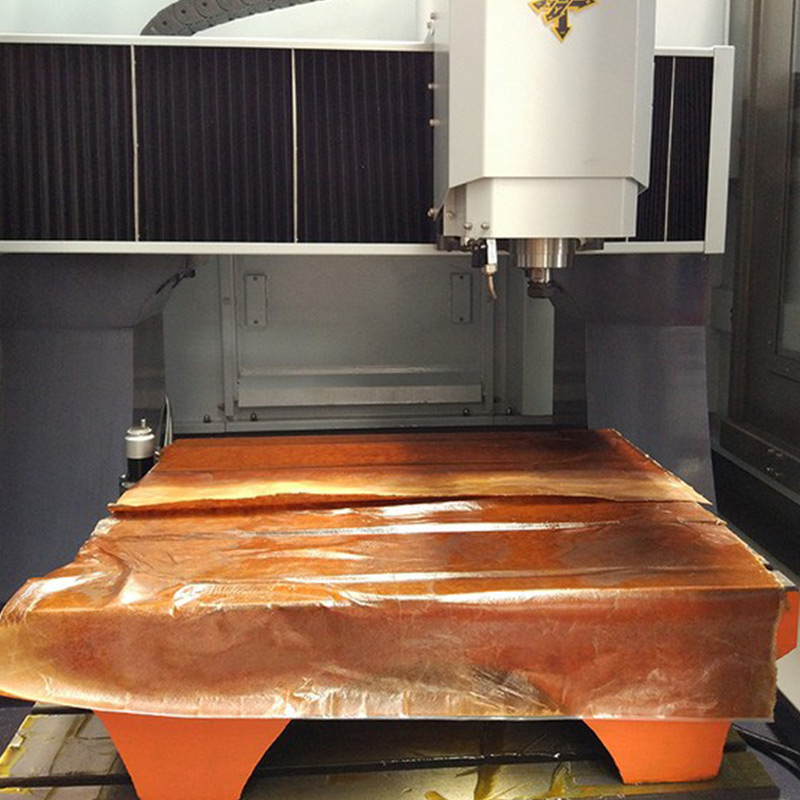

How can mold manufacturing enterprises significantly enhance machining precision and efficiency? The DC1317 large double-column CNC milling machine stands out with its smooth transmission, high rigidity, heavy machine body, and large travel range. Field tests demonstrate machining precision reaching ±0.01mm and efficiency improvements exceeding 30%. This article uncovers frontline industry insights through real case comparisons, showcasing the DC1317's superior adaptability in processing complex molds, helping manufacturers make informed choices for precision and productivity.

How the DC1317 CNC Milling Machine Elevates Mold Manufacturing Precision and Efficiency

In mold manufacturing, precision and efficiency are non-negotiable. The DC1317 large dual-column CNC milling machine has emerged as a trusted solution for shaping complex molds with outstanding accuracy and throughput. Boasting a proven machining precision of ±0.01mm and a 30%+ increase in processing efficiency, this heavy-duty CNC center answers the call for manufacturers seeking to outperform in today's competitive market.

Four Core Technological Advantages Driving Superior Mold Machining

The DC1317’s capabilities stem from four fundamental pillars that work cohesively to optimize every machining cycle:

- Stable Transmission System: The precision-ground linear guides combined with high-torque servo motors ensure smooth, rigid motion with minimal backlash. This stability is critical in attaining machining precision to ±0.01mm.

- High Rigidity Structure: A reinforced dual-column frame and thick crossbeam resist deformation under heavy cutting loads, providing consistent cutting forces and surface finish quality.

- Generous Work Envelope: Large X, Y, Z travel ranges cover most mold dimensions encountered in automotive, appliance, and injection molding industries.

- Heavy Machine Mass: The substantial machine weight dampens vibrations, allowing for higher feed rates without compromising surface integrity or tool life.

Real-World Applications: Case Studies of DC1317 in Action

Leading manufacturers specializing in automotive bumpers, household appliance molds, and precision injection molds have validated DC1317’s field performance:

| Application |

Machining Precision (mm) |

Productivity Gain |

Customer Feedback |

| Automotive Bumper Mold |

±0.009 mm |

+35% faster cycle times |

"Our toughest molds now achieve flawless finish thanks to DC1317's rigidity." |

| Household Appliance Shell Mold |

±0.011 mm |

+28% reduction in setup time |

"Stability in long runs boosts our product consistency and delivery accuracy." |

| Precision Injection Mold |

±0.01 mm |

30%+ throughput increase |

"A game-changer for tight tolerance demands, with consistent output and low maintenance." |

Head-to-Head: DC1317 vs. Competing CNC Mills

When benchmarked against comparable dual-column CNC milling centers, the DC1317 shows decisive advantages:

| Feature |

DC1317 |

Competitor Average |

| Machining Precision |

±0.01 mm |

±0.025 mm |

| Efficiency Improvement |

+30%+ |

+10%~15% |

| Max Travel Range (X*Y*Z) |

1600*1700*800 mm |

1200*1400*700 mm |

| Machine Weight |

~15 tons |

~9 tons |

Your Mold Manufacturing Challenges Solved

Mold manufacturers often struggle with inconsistent cutting accuracy, vibration-induced defects, and sluggish production cycles. The DC1317 addresses these pain points head-on:

- Precision Reliability: Eliminates dimensional variation, improving part interchangeability and reducing rework.

- Enhanced Productivity: Shortens machining times, helping meet tight delivery schedules.

- Robust Versatility: Handles diverse mold dimensions and complex geometries without performance loss.

- Long-Term Stability: Durable construction guarantees sustained accuracy over years of operation.

"Your mold challenges—our precise, efficient solutions."

Engage with Us: Share Your Mold Machining Difficulties

Are you facing challenges with mold precision, machining speed, or handling large, intricate mold designs? We invite you to share your experiences and questions in the comments below. Let’s explore how the DC1317 can transform your production line together.