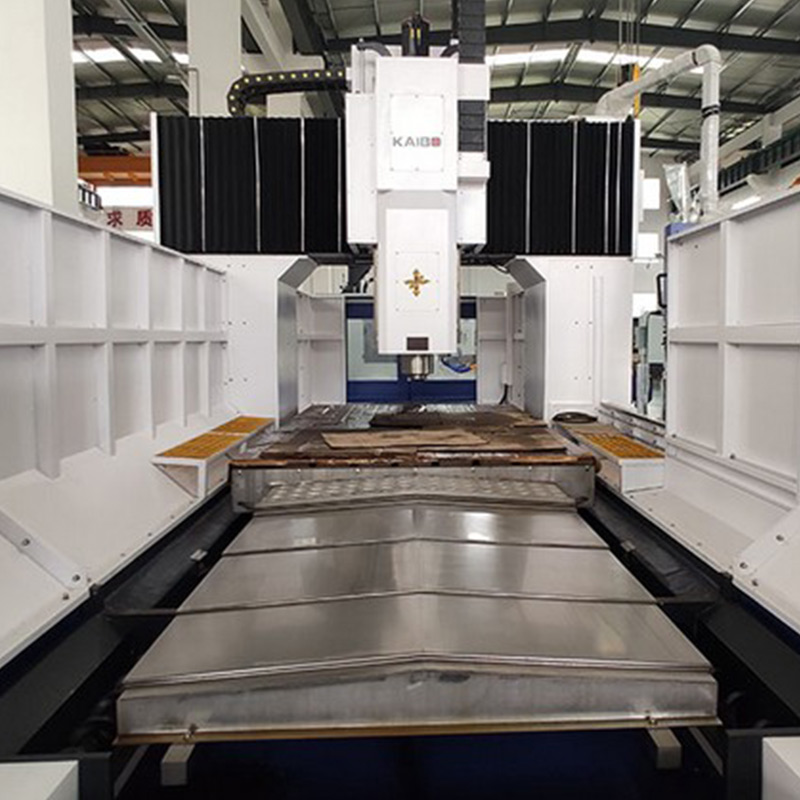

In the global manufacturing landscape, the demand for high - precision, high - efficiency machining equipment is ever - increasing, especially in the mold and heavy - part processing industries. The DC1417 large gantry CNC milling machine has emerged as the preferred choice for overseas mold factories processing heavy parts. Let's delve into why this machine has gained such popularity.

DC1417 has found extensive use in overseas mold factories, particularly those dealing with medium - to - large molds and heavy parts. It has become the go - to equipment for many leading mold factories around the world, catering to industries such as automotive parts manufacturing.

One of the key features of the DC1417 is its large gantry structure. This design significantly enhances the machine's stability and load - bearing capacity. With a robust gantry, the machine can handle heavy parts with ease, reducing vibrations during the machining process. Tests have shown that compared to non - gantry or smaller - structured machines, the DC1417 can support up to 30% more weight without compromising on stability, ensuring a smooth and precise machining operation.

The DC1417 is equipped with high - speed machining capabilities that bring remarkable efficiency advantages. It can complete machining tasks up to 40% faster than traditional milling machines. For example, in the production of a complex automotive part, a traditional machine might take 8 hours, while the DC1417 can finish the same job in just 4.8 hours. This not only shortens the production cycle but also allows factories to take on more orders and increase their overall output.

| Machine Type | Machining Time (hours) | Output Increase |

|---|---|---|

| Traditional Machine | 8 | N/A |

| DC1417 | 4.8 | 40% |

Many customers who have used the DC1417 have provided positive feedback. One customer from a well - known automotive parts manufacturing company said, "Since we started using the DC1417, our production efficiency has increased significantly, and the defect rate has dropped to less than 2%. Moreover, the machine has shown excellent long - term stability, reducing our maintenance costs and downtime."

"The DC1417 has been a game - changer for our factory. It has not only improved our production efficiency but also saved us a lot of money in the long run." - A satisfied customer

When compared with similar products in the market, the DC1417 stands out with its unique technological features. Its advanced control system allows for more precise programming and real - time monitoring, ensuring higher machining accuracy. In addition, its energy - efficient design reduces power consumption by up to 20% compared to some of its competitors, making it a more sustainable and cost - effective choice.

The DC1417 comes with a set of systematic solutions for common machining problems. Whether it's dealing with difficult - to - machine materials or complex part geometries, the machine can adjust its parameters automatically to ensure optimal machining results. This flexibility makes it suitable for a wide range of applications in the mold and heavy - part processing industries.

In conclusion, the DC1417 has become the industry's top choice due to its stable gantry structure, high - speed machining capabilities, long - term reliability, and cost - saving features. It offers a comprehensive solution for overseas mold factories and heavy - part processing enterprises, making production more efficient and cost - effective. If you want to take your manufacturing to the next level and experience the benefits of the DC1417 for yourself, click here to learn more or contact us for a consultation.