In the realm of large-scale mold manufacturing, companies often encounter a series of challenges. Precision fluctuations are a significant headache. For instance, in some traditional milling machines, the precision error can reach up to ±0.05mm, which is far from meeting the requirements of high - end molds. This leads to a high rate of rework and a low yield, directly affecting production efficiency and cost. Additionally, insufficient equipment rigidity is another common issue. When processing large - sized molds, the machine may vibrate, causing uneven cutting and affecting the surface quality of the mold. These problems not only limit the production capacity but also reduce the competitiveness of enterprises in the market.

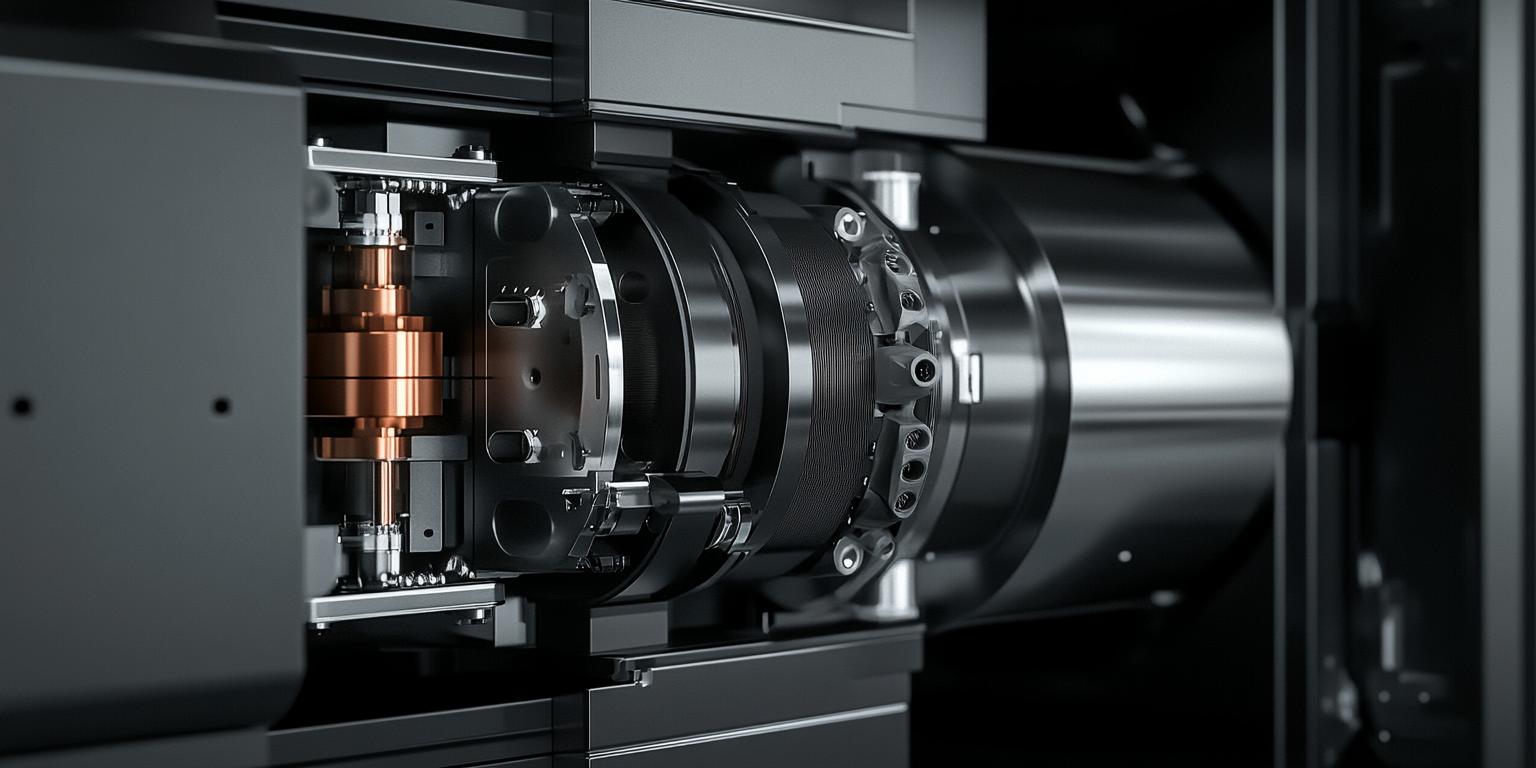

The DC1520 is equipped with a gantry structure, which significantly enhances its stability. Compared with some ordinary vertical milling machines, the gantry structure can effectively resist external forces and vibrations during the machining process. This ensures that the machine can maintain a stable state even when processing large - sized and complex molds, greatly improving the machining accuracy and surface quality of the mold.

The three - axis travel of DC1520 reaches 1500×2000×720mm, which can cover the size range of most mainstream large - scale molds. In the market, about 80% of large - scale molds fall within this size range. This means that the DC1520 can process a wide variety of large - scale molds without the need for frequent adjustments or the use of additional fixtures, saving a lot of time and cost for enterprises.

The DC1520 boasts high precision, with an accuracy level of ±0.01mm. This high - precision machining can significantly reduce the rework rate. For example, in a mold manufacturing enterprise, after using the DC1520, the rework rate decreased from 15% to less than 5%. At the same time, the high - rigidity design of the machine ensures that the cutting process is more stable, which can effectively improve the yield of products. The yield can reach over 95%, compared to about 80% in some traditional machines. Moreover, the stable cutting process also extends the service life of the cutting tools. In general, the service life of cutting tools can be extended by about 30% when using the DC1520, reducing the tool replacement cost for enterprises.

Let's take a well - known mold manufacturing company as an example. Before using the DC1520, they faced problems such as long production cycles and low product quality when processing large - scale automotive molds. After introducing the DC1520, the production cycle was shortened by 30%, and the quality of the produced molds was highly recognized by customers. This not only increased the company's order volume but also enhanced its brand image in the market.

| Model | Precision | Rigidity | Three - Axis Travel | Price - Performance Ratio |

|---|---|---|---|---|

| DC1520 | ±0.01mm | High | 1500×2000×720mm | High |

| Similar Model A | ±0.03mm | Medium | 1200×1800×600mm | Medium |

As shown in the table, the DC1520 has obvious advantages in precision, rigidity, and three - axis travel compared with similar models. In terms of price - performance ratio, it also outperforms most competitors, providing enterprises with more cost - effective solutions.

The DC1520 serves as a powerful tool for enterprises to break through the bottlenecks in large - scale mold processing. It helps enterprises improve production efficiency, reduce costs, and enhance product quality. By choosing the DC1520, enterprises can gain a competitive edge in the market and win more high - end mold orders, thus creating a new benchmark for mold processing.

Are you still struggling with the problems in large - scale mold processing? Do you want to enhance your enterprise's competitiveness in the market? If so, why not consider the DC1520? Click here to learn more about the DC1520 and take your mold processing to the next level!